World's Leading Provider of Used Machinery

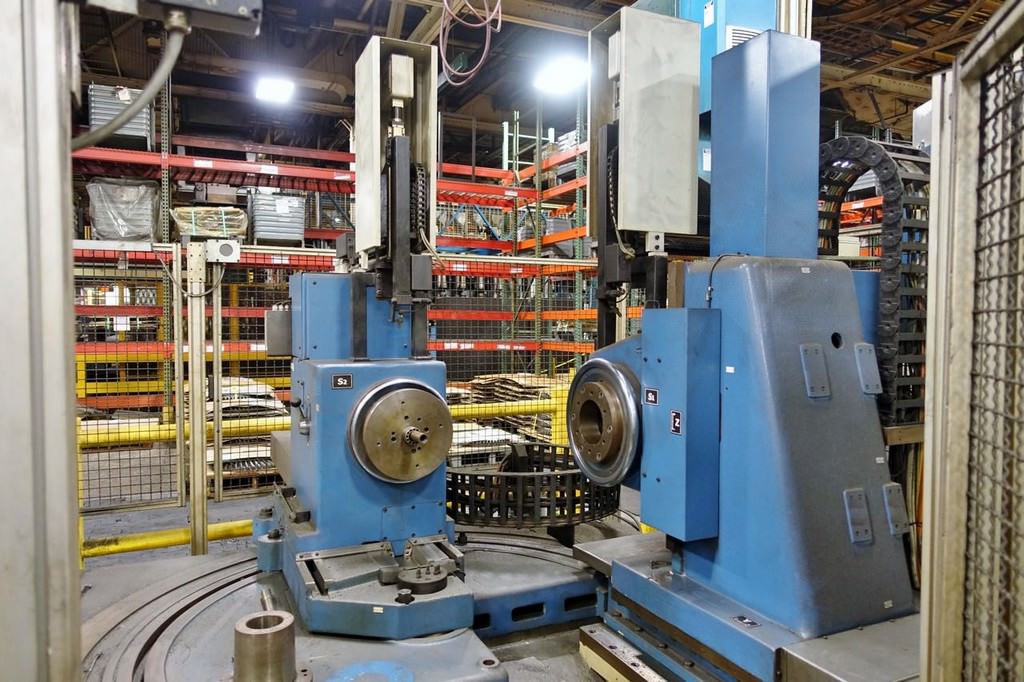

WELTER Model UHT-800 CNC Universal Bevel Gear Checker

Model:

UHT-800

Age:

2009

Ref#:

26863

Prestige Equipment is the world's leading provider of WELTER Model UHT-800 CNC Universal Bevel Gear Checker & machine tools & fabricating equipment. Take a look at our wide selection of new and used Gear Testers for sale.

Product Specifications

View Additional Specs

Product Specifications

SPECIFICATION:

Maximum Gear Diameter

800 MM

Shaft Angle Between The 2 Spindles

45-180 Degrees

Distance, Pinion Face To Center

211 MM -570 MM

Distance, Spindle Face To Center

500 MM

Driving Headstock Horiz. Movement

60 MM Forward

Driving Headstock Horiz. Movement

180 MM Backward

Maximum Hypoid Offset

115 MM

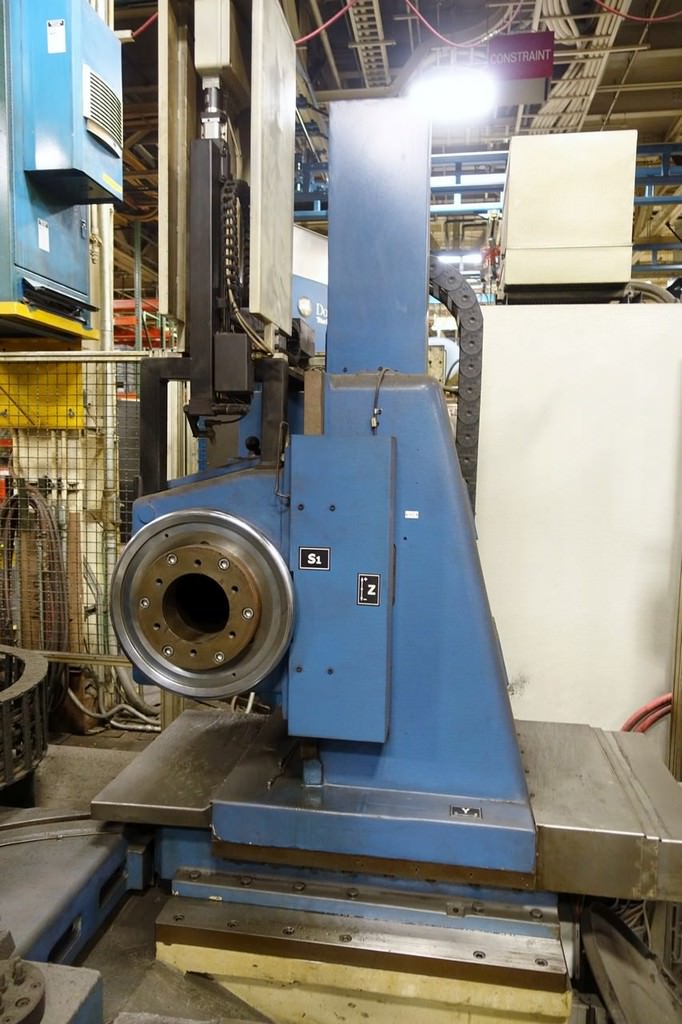

Diameter, Pinion Spindle Bore

152 MM (60 Taper)

Taper Of Pinion

60 Taper

Spindle Speed Pinion Headstock

0-200 RPM

Spindle Speeds

1000 RPM / 500 RPM

Main Spindle Motors, S1/S6

4 KW / 4 KW

Floor Space L x W x H

3683 MM x 2692 MM x 2000 MM

Approx. Weight

10977 KG .

CNC CONTROL:

Geartec CZ 4-Axis CNC Control For Pinion MD, Gear MD, Sliding Base, Pinion

Offset

BASIC SINGLE FLANK SOFTWARE:

Single Flank Inspection With FFT Analysis

Interface Software For Digital Tooth Contact Display Of Inspection Result

With A Digital Camera

FULLY AUTOMATED SINGLE FLANK OPERATION:

Auto Stock Dividing Using Non-Contact Sensing System To Detect Tooth Gap

Automatic Or Foot Actuated Clamping Of The Pinion Or Gear

Automatic Positioning To Pre-Determined Baclash

Best Backlash Positioning Based On Single Flank Running Characteristics

Automatic Programming Of Single Flank Test Cycles

Auto Movement To Pre-Determined Position For Bearing Pattern Inspection For

Digital Image Capture

Digital Image Capture With Automatic Storage Of The Image With The Single

Flank Data Inspection Report

AUTOMATED FUNCTIONS:

The Operator Brings Gear And Pinion Manually To The Machine Or Robot

Automatic Or Manual Clamping Of The Pinion And Gear

Automatic Find Correct Position Of Tooth Gap By Non-Contact Position Sensors

Inspection Of Angular Position Of Gear And Automatic Position Of Respective

Axes

Automatic Approach To Pre-Determined Backlash.

Automatic Cycle Start Of Single Flank Inspection For Respective Positions

Automatic Machine Movements To Test Pattern Position For Bearing Pattern

Inspection For Digital Imaging Capture

Digital Image Capture Of Contract Pattern & Automatic Saving Of Digital

Imate To The Test File

Request a Quote Today

Enter your email address for detailed product information.

OR Contact Us at 631-249-5566

[email protected]

Get Financing

One Click Financing. Learn more here.

One Click Financing. Learn more here.

Auctions & Liquidations

Looking for a great deal? Click here.

Looking for a great deal? Click here.