Worldwide Industrial Auctions & Liquidations

2-Day Onsite & Online Auction

DAY 1: Spectacular Multi-Million Dollar Offering! Late Model Fabricating & Material Handling

DAY 1: LATE MODEL FABRICATING & MATERIAL HANDLING: Fiber & Co2 Lasers – New as 2015! 2015 River Sheet Delivery System, Amada 242 Ton Robotic Bending Cell, 2007 Amada 7-Axis Brake, (2) 2013 550 Ton Dener CNC Press Brakes, (3) 7-Axis Robotic Welding Cells, (4) Viking Blast Cabinets – New as 2014, Late-Type Plasma Table, Forklifts & Combi-Lifts, Manlifts, Bridge Cranes up to 10-Ton – New as 2015, PLUS MUCH MORE!

June 12-13

10:00AM EST

Bedford, PA

Contact for Sale

Inspection Date

June 11 8:00AM -4:00PM

Or By Appointment

Or By Appointment

In Conjunction With

Sale Information

DAY 1: FABRICATING EQUIPMENT & MATERIAL HANDLING:

LASERS:

- 2015 MITSUBISHI ML3015NX-F40 (S), 4 KW Fiber Laser, Y-axis 63”, X-axis 126”, Nozzle Changer, Automatic Pallet Changer, linear drive Z-axis 4.7”, (3) scrap draws, chiller unit, Mitsubishi LC30BF 64-Bit PC Touch Screen Ctrl., Mitsubishi 4000 watt fiber laser resonator, SN: 153NF40044

- 2015 MITSUBISHI ML3015EX(S), 6 KW CO2 Laser, 60” x 120”, Nozzle Changer. Automatic Pallet Changer, Mitsubishi 60XF 6000 watt resonator, chiller unit, SN: 1560XF0074

- 2015 RIVER CM510 MSCII Sheet Storage and Delivery System, capability 5’ x 10’, 6000 Lbs., 8 Bays, maximum 153 pallets, equipped with (60) pallets, stacker crane, rear cart station with Pin Scissor table, (4) Part unloading carts 11,000 lbs. per cart, system set-up to handle (3) lasers

- 2009 PRIMA PLATINO 2040, CV5000 5KW CO2 Laser, Primach-20L 64-Bit CNC, 80” x 160”, 4th axis Rotary Chuck for Tube Cutting, Convergent CV5000 Laser Resonator, Automatic Pallet Changer, Chiller, Dust Collector, Prima TowerServer (10) Shelf Tower with Sheet Load/Unload System, SN: 4320212

PRESS BRAKES:

- 2011 AMADA HDS2204NTW Servo Hydraulic Brake/ Astro 165 Robotic Bending Cell, 242 Ton x 168.5”, 148” between housings, 9.84” stroke, 17.72” throat, 26” open height, Yaskawa 6-Axis Robot, Part Load/Unload, AMNC/PS 8-Axis CNC Brake Controller, options; (6) part handling fixtures, Bi-J high speed precision bend sensor 90-150 degree angle check range. SN: 22403356

- 2007 AMADA FAB-III 1253NT 7-Axis CNC Brake, 138 Ton x 10’, 118” between housings, 5.9” stroke, 16.5” open height, 15.76” throat depth, AMNC-PC 7-Axis CNC, bed crowning, 5-axis back gauge, One Touch European Upper Tool Clamps, electric foot switch and full length treadle control, SN: 12533248

- 2013 DENER DE500-40-ACLLCCS-TNDR 550 Ton x 4050mm CNC Press Brake, (2) Brakes set-up in Tandem 1100 Ton x 26’ Overall Bending Length, (2) ESA 5-Axis CNC Controls, 2-Axis heavy duty 40” range back gauge, (4) manual Z-Axis fingers each brake, (2) front support arms each brake, 159.4” overall bed length each machine, 24” throat depth, 29” throat height, approximately 19” stroke, lower crowning die, European style tool clamps, SN: 35040-13108, SN: 35040-13107

- GASPARINI P0A 160, 176 Ton x 12’ Brake, PC800 CNC Control, 5-axis cnc back gauge, dual foot switch control

- GASPARINI PBS 045, 49.5 Ton x 6’ Brake, Delem DA65 CNC Control

PRESS BRAKE TOOLING:

- Large quantity of European and American style press brake dies

- Large quantity of European filler blocks

- 26’ long adjustable lower bending die

BENDING ROLL:

- 2005 AMERICOR LH-80/5, 3-roll single pinch, 1.6 mm x 1950 mm, 61” roll length, 3” roll diameter, power rear roll tilt, hydraulic pinch and bending roll adjustment, SN: 3190181

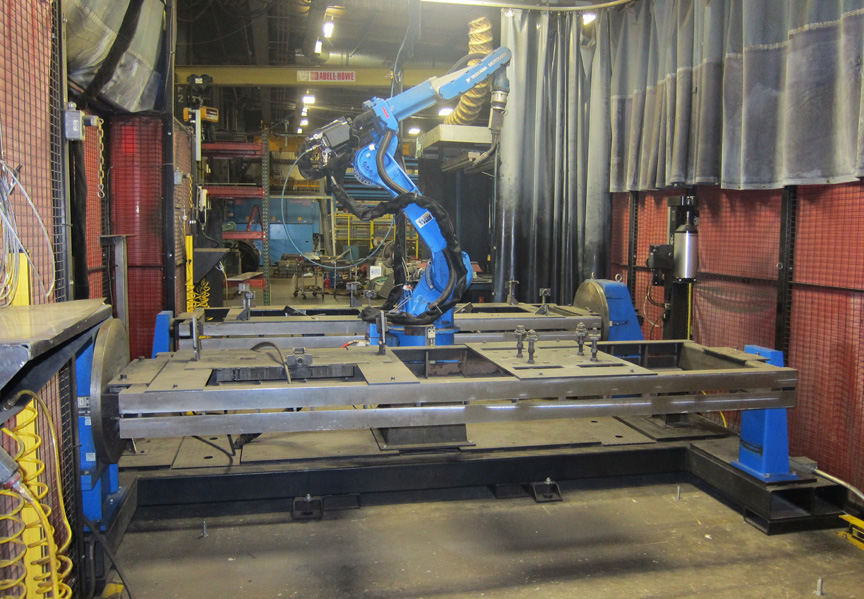

ROBOTIC WELDING CELLS:

- 2011 YASKAWA Motoman MA1900 7-Axis, DX100/ MA1900 Controller, Teach Pendant, MILLER Axcess 450Di power supply, Dual Station Trunnions 114″ x 48″ x 3300# cap., Motoman Touch Sense Comarc III option, Tregaskiss head cleaner, SN: S1V138-12

- 2011 YASKAWA Motoman MA1900 7-Axis, DX100/MA1900 Controller, Teach Pendant, MILLER Axcess 450Di Power Supply, Dual Station Trunnions 114″ x 48″ x 3300# cap., Motoman Touch Sense Comarc III option, Tregaskiss head cleaner, SN: YRMA01900-A00

- MOTOMAN UP6 AXIS, 13.23 lbs. load capacity, 54” reach, YASNAC XRC2001, MILLER Auto Envision II weld power supply, Teach Pendant control, (2) station turntable, SN: S1M618-11

PLASMA CUTTING TABLE:

- 2013 CUTTING SYSTEMS INC KODIACK, Hypertherm Edge Pro CNC Control, 10’ x 46’ effective cutting area, 10’ x 47’ x 26” multi-zoned down draft cutting table with removable slag pans, 55’ floor mounted rail, (2) Plasma Torch Stations with Hypertherm ArcGlide torch height control, (2) Hypertherm Hy-performance Plasma HPR 400XD Power Supplies with Power Pierce Shield Technology with Water Cooled Shield, w/ (2) Oxy Cutting Heads

BAND SAWS:

- 2013 COSEN C520-NC HORIZONTAL BAND SAW, Double Column, 20.5” x 22” capacity, 250” x 2.1” x 0.06” blade size, 7.5 HP blade motor, 2 HP hydraulic motor, coolant, auto bar-feed, programmable control, (2) Available, SN’s: C1020468, C1010425

- HYD-MECH S25A HORIZONTAL BAND SAW, 18” x 27” capacity, 18” round, 1.5” blade, Auto Bar-feed, SN: 9019182

- DO ALL 6012-3 VERTICAL BAND SAW, 60” throat, power feed table, vari-speed, blade welder, SN: 199-67118

BLAST CABINET MACHINES:

- 2014 VIKING 120T, 120” Dia. Table, 20,000 Lb. Weight Capacity, 60” Max. Height, (4) 15 HP blast wheels, full liner upgrade package replaceable ½” thick cast chrome entire opposing wall, V-Slot Two Swing Doors, auto abrasive adder, abrasive trap

- 2012 VIKING SH3660 Spinner Hanger, (2) 34” x 60” Blast Chambers, (2) 15 HP direct drive blast wheels, 750 Lbs. hook part weight, multi-station indexing, full liner blast cabinet option, V-Notch option for overhead lifting, abrasive trap, digital blast timer

- 2008 VIKING 7260T, 72” Dia. Table, 60” Max. Work Height, (2) 15 HP blast wheels, cabinet ½” thick replaceable cast wear resistant Chrome/moly liners

- 2004 VIKING 48T, 48” Dia. Table, 34” Max. Work Height, 3200 Lb. weight capacity, cabinet ½” thick replaceable cast wear resistant Chrome/moly liners, 20 HP, 15” diameter, 8 blade center fed blast wheel, abrasive recycling system, digital blast timer

IRONWORKER:

- GEKA HYDRACROP 80/A, 88 ton, 5” x 5” x ½” angle, 18” x 5/8” flat bar, 12” throat, dual work stations, dual electric foot switches, coper/notcher, SN: 12642

BELT SANDER:

- 37” TIMESAVER 3121-13-04 Vertical Belt Sander, Dual Head, Wet-Type, E1070 Controls, S/N 30962

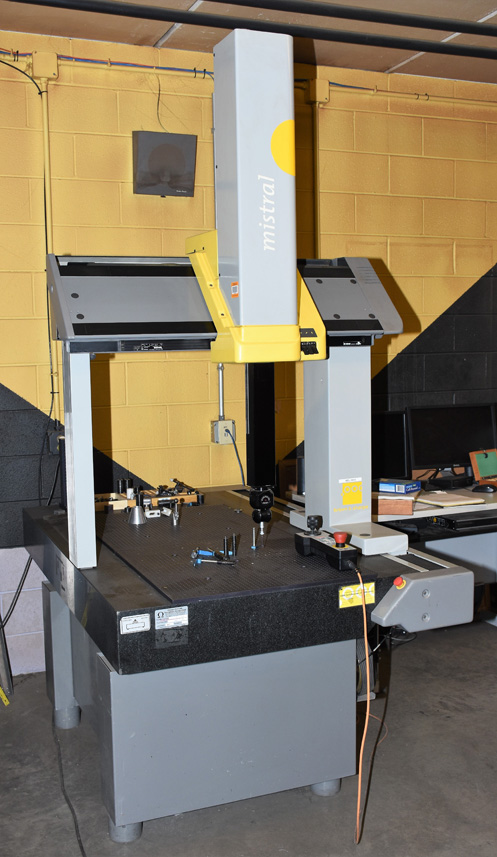

INSPECTION / QUALITY CONTROL:

- 2013 FARO ARM Platinum BFD-162 Portable CMM

- 2012 FARO ARM Edge Portable CMM with Laser Tracker

- 2008 AMADA/VIRTEK LPS-1DS flat part to drawing laser measuring system, 48” x 48” table, SN: 08016442

- BROWN & SHARP Minstral 7-10-5 CMM, 6-Pos. Probe Changer, 61” x 35” Granite Table

- STARRETT AGC-HGC2018-16 CMM, Quadra Chek 300

- MITUTOYO B706 CMM with Quadra Chek 300, 50” x 42” Granite Table

- 14” GAGEMASTER Series 20 Optical Comparator

- 96”x48”x12” Granite Plate, 72”x48”x10” Brown & Sharpe Granite Plate, Rockwell Hardness Tester, CMM Threaded Set-up Plates, Micrometers, Vee-Blocks, Pin Gage Sets, Verniers, Intra Mics, Thread Gages, Calipers, Groove Mics, Indicator Stands, Gage Blocks, Inspection Kits, Fault Testers, Height Gages, Etc – Hundreds of Lots!

PAINT DEPARTMENT:

- RAPID ENGINEERING BATCH CURE OVEN Mdl. 121225, 500 degree Fahrenheit max. operating temperature, 2.4 million BTU/Hr. burner capacity, 2400 ACFM safety vent exhaust fan, 12 minutes min. pre-ignition purge, digital controls, 160” W x 25’ long x 12’ H,, double doors, serial number: 082103

- PHOSPHATE RINSE SYSTEM, (6) stainless steel tanks, 7.5 HP vacuum pump, gantry crane system with (3) 500# Electric Hoists, Rinse & Desmutter

- PAINT BOOTHS (2) 14’ wide X 27’ long X 12’ high, double door, rear exhaust filtration system

- HARBEL PAINT SHAKER, 5 gallon capacity

- UNIRAM 900EP2SS solvent still, URS900 Touch Container, Timers, Stainless

- ENCON DE2B evaporator, SN: 37280, mfg. 2012, 42″ x 24″ dia x 36″ height

- JRI SKFL-500 parts washer, Front Loading, wash/cycle tanker, heater

- DRYING RACKS, large quantity of parts drying racks

CRANES, BRIDGE & ROLLING GANTRY:

- (2) 2015 ALTOONA 10 Ton x 58’ Span, Top Running, Single Girder, Demag 10 Ton Hoist, 20’ Lift, Radio Control, Two Available

- 2013 KONE 10 Ton, 57’1” Span, Double Girder, 20’ Lift, Radio Control

- PROGRESSIVE 10 Ton, 57’ Span, Double Girder, 20’ Lift, Radio Control

- HANDLING SERVICES INC. 2 Ton, 40’ Span, Pendant Control Crane System with Rail and Uprights

- (2) CRANE-TECH 1 TON, 40’ Span, Single girder, under hung bridge, pendant controls

- (2) KONE 1 Ton x 40’ Span, single girder. Under hung bridge, pendant controls

DUST COLLECTORS:

- DONALDSON TORRIT DF3-6, S/N: TG568769-001, (6) cartridge, 7.5 HP

- VIKING SFC4-2, S/N: 60065819, (4) Cartridge, 7 HP

- (4) ACT (AIR CLEANING TECHNOLOY) ACT3-24 SYSTEMS, 30 HP, (12) cartridge, S/N: 15594 Mfg. Date: 2013, S/N: 15593 Mfg. Date: 2013, S/N: 15592 Mfg. Date: 2013, S/N: 15575 (20 HP) Mfg. Date: 2013

- FARR 6D, (6) filter cartridges, (1) drum, SN: 95DC23052

- UNITED AIR SPECIALTIES FJL-2, S/N: 60044735

WELDERS / WELD POSITIONERS / BEVELER:

- ARONSON MD HD 20PTVR-1.22 Power Tilt, Var Speed, 2000# Capacity, S/N 632, 18” Diameter

- ALL FAB PS2F5A Vertical Welding Positioner (bench-type with tailstock), PANJIRIS Welding Positioner with 8″ 3-jaw chuck

- HYPERTHERM POWERMAX 1650 G3 Series, S/N 1650-015962

- HYPERTHERM POWERMAX 1000 G3 Series, S/N 1000-027791

- (1) MILLER DIMENSION 452 400 AMP, CC-CV-DC, W.P.S, w/ Series 70 WF, S/N LC677606

- (4) MILLER DELTAWELD 452 CV-PC, 450 AMP, W.P.S w/Miller 70 Series WF, S/N MC180452V, MB390624w, MC280202C, MB390625W

- (2) MILLER MD XMT 450 MPA 400 AMP W.P.S. w/ Miller 5-74 MPS WF, S/N MC3606584, MC360657w

- (4) MILLER SYNCROWAVE 350LX 300/350 AMP, W.P.S with Tig Gun, Chiller, S/N LC 499706, S/N LC346229

- (1) MILLER MP65E CP DC, W.P.S, S/N JA43816

- (6) MILLER MILLERMATIC 350 300 AMP, W.P.S., w/ wire feed, (Phase 1) S/N LF129482, LE282353, LH400778B, LE282352, LE282352, MB391129N

- EWALD 1960-1Z Rotary Seam welder w/ Nitron Control S/N 203051

- HECKS CHP-12 Beveler

FORKLIFTS:

- UNICARRIERS MODEL MCP1F2A25LV 4400# Capacity, LPG Forklift, 187” Lift, solid tires, side shift, 48” forks, 961 hours on meter, S/N CP1F2-9W22399

- HYSTER MODEL S120XLS 11700# Capacity, LPG Forklift, 184” lift, Solid tires, Side Shift, 72” Forks, 1761 hours on meter, S/N D004V091515

- CATERPILLAR MODEL GC25K 4350# Capacity, LPG Forklift, 188” Lift, Solid Tires, Side Shift, 48” Forks, 8201 hours on meter, S/N AT82D03641

- CATERPILLAR MODEL C5000 4750# Capacity, LPG Forklift, 187” Lift, Solid Tires, Side Shift, 42” Forks, 4408 hours on meter, S/N AT9001534

- NISSAN MODEL MCPL02A25LV 3150# Capacity, LPG Forklift, 187” Lift, Solid Tires, Side Shift, 42” forks, 6215 hours on meter, S/N CPL02-9P2989

- NISSAN MODEL MCP1F2A25LV 4400# Capacity LPG Forklift, 187” Lift, Solid Tires, Side Shift, 42” Forks, 3160 Hours on meter, S/N CP1F2-9W1417

- COMBILIFT MODEL CL42173DA49 17300# Capacity, Side-Loader, Forklift Truck, MFG’d 06/08, Gasoline engine, 3-Stage mast, 96” forks, 60” carry-deck, 24” load center rating, 3-Wheel Chassis, Enclosed cab w/heat, 6639 hours on meter, S/N 7021

MANLIFTS:

- GENIE MODEL 2-30/20HD Battery powered articulated boom manlift, 31 ft maximum platform height, 500# Capacity, 11L-155L Foam Filled Tires, S/N 30-87-1481

- JLG MODEL E300AJ Battery powered articulated boom manlift, (2006) 30’ maximum Platform Height, 20” maximum horizontal reach, 500# Capacity, 25 x 7-12 solid tires, fly jib, S/N 0300091141

- JLG MODEL 2630ES Battery Powered scissors Lift, (2005), 25’4” Maximum platform height, 500# Capacity, 24 Volt, 449 Hours on meter, S/N 0200131062

FLOOR CLEANERS:

- ADVANCE”Advenger” Ecoflez

- ADVANCE “Terra 430B”

- FACTORY CAT Floor Sweeper

LIQUID OXYGEN / NITROGEN TANKS:

- UCAR LIQUID OXYGEN TANK 1500 Gallon, Nat’l Bd, No 5640, S/N TM-1500 20166, M.A.W.P 250 PSI, M.A.T.R. -320 degrees F to +150 degrees F IT, SH .348” min, HD .328” mm, R-Ell (1975)

- TAYLOR-WHARTON LIQUID NITROGEN TANK S/N UT-1500 G1885 (2004), M.A.W.P. 500 PSI @ 100 degrees F, M.D.M.T -320 degrees F at 500 PSI, SH 588, HD 551, R-Ell, Nat’l BD, No 70785

TRUCKS:

- (2001) FORD F350XLT SUPER DUTY 4×4 Pickup Truck, VIN: 1FTSX31F91EB02863, Diesel, Extended Cab, Snowplow Attachment w/ plow, 233730 Miles on Odometer

- (2008) FORD F750 XLT SUPER DUTY 22’ Box Van Truck, VIN: 3FRWF75G08V666921, Diesel, 6 Speed, Air Ride, Supreme 22’ Aluminum Van Body w/Roll-VR Door, PW/PL AC, 86975 miles on odometer

PLANT SUPPORT AND TOOLING:

- Denray 2872G DowndraftTables, Lay-out Tables, Skates, Mcullogh Mdl. 100SS Self Dumping Hoppers, Burr-King Belt Sanders, Welding Curtains, Pallet Rackings (Apprx 50 Sections), Hand & Power Tools, Tool Cabinets, Double Door Storage Cabinets, Large Qty of CNC Tooling, Tooling Carts, Vidmar Cabinets, Boring Heads, Collets, Vises, 50-Ton H-frame Press, Greenerd Arbor Press, Chicago CP450 Compression Riveter, Unitek 300 Tap Disintegrator, Metalx Stress Tester, Sand Blast Pot, 42” Bishamon Rotary Scissor Lift Table, 8000# Sheet Lifter, 10” Haas Rotary Table, Vises, Perishable Tooling, Tool Holders, Kurt “Carvlock” Tower, Pneumatic Flex Arms, Polishers, Lifting Chains & Straps, HUNDREDS OF LOTS!!

Auction Location

15 Commerce Court, Bedford, PA 15522 Get Directions