Worldwide Industrial Auctions & Liquidations

Onsite & Online Auction

Turbine Manufacturing Facility – Large Capacity CNC Turning & Boring Machinery

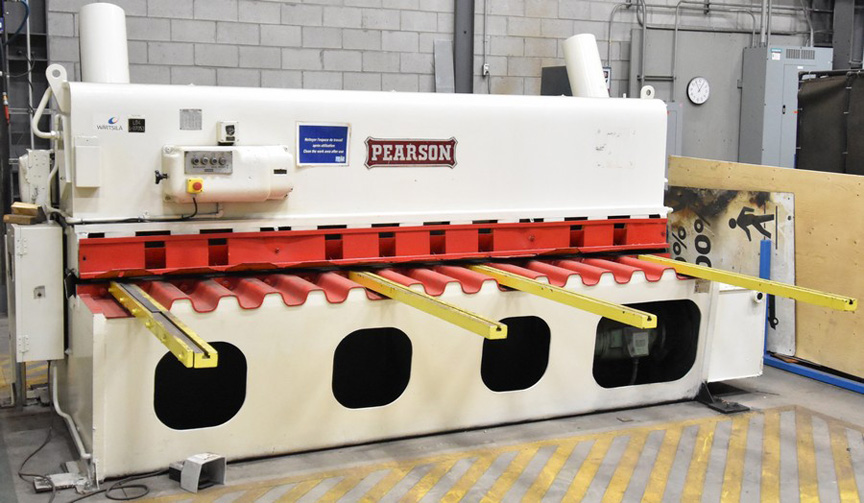

FEATURING: TOSHIBA (2012) TSS 40/67C(S), 157”/263” CNC VBM with milling, 102” max turning height, Fanuc 31i-A CNC control; TITAN (IMUAB) SC 50/67, 196”/263” CNC VBM with milling, 300 Ton table wt. capacity, RE-MANUFACTURED 2001 SIEMENS 7-axis CNC control; POREBA 54” x 192” heavy duty CNC lathe; TOS SU-100, 40” x 300” heavy duty engine lathe; POREBA TR-135-B1-3M, 40” x 120” heavy duty engine lathe; (2) TOS SN71C, 28” x 157” engine lathes; COMPLETE ROBOTIC THERMAL METAL SPRAYING SYSTEM consisting of a 6 axis ABB robot, bridge crane, POREBA 60” x 288” turning lathe, TAFA JP-5000 spray system, Thermach AT-3000 plasma (2014), TITAN 96” dual ram CNC VBM; O-M LTD 63” CNC VBM; STANKO 1516, 54” CNC VBM; STANKO 1L532, 110” VBM; TOSHIBA TX16, 63” VBM; TOS (2004) W100, table type HBM; TOS W100A, table type HBM; 300 Ton horizontal hydraulic wheel press; (2) IRD balancing systems; STANDARD MODERN 20” x 60” CNC flatbed lathe; HWACHEON 18” x 80” engine lathe; (3) TOS SN50C, 16” x 78” engine lathes; HWACHEON 18” x 72” engine lathe; PYROTHERM (2016) natural gas fired oven; 20’ x 30’ Paint Booth; CANABLAST 10’ x 18’ shot blast booth w/ media reclamation; MP TECH 15’ x 15’ car bottom blast booth; CANABLAST shot blast w/ reclamation; GRIEVE batch oven; PEARSON 10’ x .375” shear; P&H 16,800 LB elevating tilt & rotate welding positioner; (3) IRCO & RANSOME tilt & rotate welding positioners; LANDIS 36” x 120” cylindrical grinder; MAS VR8, 8’ radial arm drill w/ rotary table; MAS VR4, 4’ radial arm drill; JONES vertical slotter; ABRATECH dust collector; ACCU late model chiller; (2) NEDERMAN portable fume extractors; CHURCHILL vertical spindle rotary surface grinder; ALSO featuring: welders, adjustable racking, box tables & MUCH MORE!

June 20, 2019

10:30AM EST

Quebec, Canada

Sale Information

CNC VERTICAL BORING MILLS:

- TOSHIBA (2012) TSS 40/67C(S), CNC vertical boring mill with milling, FANUC 31i-A CNC control, 157” table diameter, 263” turning diameter, 102” max turning height, 59” ram stroke, 25 HP live spindle motor, live spindle speeds to 2000 RPM, 55,000 LB table weight capacity, table speeds to 80 RPM, C-axis table, right angle milling head, 24 ATC, chip conveyor, elevating operators station, s/n 510511

- TITAN (IMUAB) SC 50/67, CNC vertical boring mill with milling, SIEMENS SINUMERIK 840C 7-axis CNC control, 196” table diameter, 263” max turning diameter, 149” max turning height, 110” cross rail vertical travel, table speeds to 32 RPM, C-axis table, right hand turning ram with 78.74” vertical travel, left hand milling and turning ram with 49.21” vertical travel, 67 HP milling spindle, milling spindle speeds 6-630 RPM, 2-axis CNC gimbal head, universal milling head, right angle milling head, Completely Re-Manufactured in 2001 by Dorries Scharmann with SIEMENS 7-Axis CNC Controls, New Electrics, New Hydraulic System, New Coolant System, New Servo Drives, New Lubrication System, New Ball Screws [Machine Has Been Professionally Dismantled and Packed For Export Shipment, Located in York, PA USA]

- STANKO 1516 CNC vertical boring mill with FAGOR 8055 CNC control (RETROFIT 2009) 55” table diameter, 63” max swing, 39.37” max turning height, 33.50” z-axis vertical travel, 27.55” head horizontal travel, ±45 degrees head swivel, 30,000 LBS max table capacity, speeds to 112 RPM, 80 HP spindle drive, chip guards, safety fence enclosure with interlocks, s/n 2517

- TITAN SC27 CNC vertical boring mill with retrofit FAGOR 8055 CNC control, 2-ram heads, 98” table diameter, 104” max swing, 74” max turning height, 47.24” vertical ram stroke, 30,000 Lb table capacity, speeds to 112 RPM, 80 HP spindle drive, chip guards, safety fence enclosure with interlocks, s/n n/a (NOT IN SERVICE)

- O-M LTD CNC vertical boring mill with FAGOR 8055 CNC control (RETROFIT 2007), 63” table diameter, 80” max swing, 43” Z-axis vertical travel, chip guards, safety fence enclosure with interlocks, s/n n/a

VERTICAL BORING MILLS:

- STANKO 1L532 vertical boring mill, 110” table diameter, 125” max swing, 62.99″ max turning height, 47.24″ head stroke, ±35 degrees head swivel in .01″ increments, 5 station turret on RH head, RH side ram head, 32,200 LBS max table capacity, speeds to 63 RPM in (12) ranges, 46 HP spindle drive with retrofit YASKAWA GPD506/P5 VFD drive, ACU-RITE 4-axis digital readouts, full pendant controls, coolant, chip guards, safety fence enclosure with interlocks, s/n 762

- SHIBAURA TX-16 vertical boring mill, 5-position turret, 63” table diameter, 78.74″ max swing, 59″ max turning height, 39.37″ head stroke, ±30 degrees head swivel, 28,000 LBS max table capacity, speeds to 160 RPM, 40 HP spindle drive, chip guards, full pendant controls, safety fence enclosure with interlocks, s/n 320148

TABLE TYPE HORIZONTAL BORING MILLS:

- TOS (2004) W100A table type horizontal boring mill with 3.93″ spindle, 49″x49″ table, travels 68″ longitudinal, 62″ cross, 44″ vertical, 35″ spindle stroke, ISO 50 spindle taper, speeds to 1120 RPM, 15 HP spindle drive, TOS SP100/800 spindle clamping support attachment, TOS SP100/500 spindle clamping support attachment, TOS FP40-100 milling head attachment, coolant, spindle & cutting guard with safety interlocks, ACU-RITE 4 axis DRO, s/n 240-05 3.487

- TOS (2002) W100A table type horizontal boring mill with 3.93″ spindle, 49″x49″ table, travels 68″ longitudinal, 62″ cross, 44″ vertical, 35″ spindle stroke, ISO 50 spindle taper, speeds to 1120 RPM, 15 HP spindle drive, TOS SP100/800 spindle clamping support attachment, TOS SP100/500 spindle clamping support attachment, TOS FP40-100 milling head attachment, coolant, spindle & cutting guard with safety interlocks, HEIDENHAIN 5 axis DRO, s/n 03-793.438

- SELLERS table type horizontal boring mill with ACU-RITE DRO, tailstock

FLOOR TYPE HORIZONTAL BORING MILLS:

- Waldrich 6.3″ CNC Floor Type Horizontal Boring Mill With Allen Bradley 9-240 CNC Control Swiveling Headstock, Travels X-354″, Y-163″, W-38″, Z-89″, A-Axis Swivel +/- 135 Degrees, 6-1001 RPM, 36″ Facing Head, 120″ Rotary Table, 100 Ton Capacity, 360 Degree B-Axis Contouring, Auxiliary Jib Crane, Chip Conveyor

- Gray 6″ 6600FQ Floor Type Horizontal Boring Mill, X-305″, Y-72.5″, Z-46.8″, W-30″, 6-900 RPM, 75 HP Spindle Motor, 0-120 IPM Feed Rate, Chip Conveyor

CNC LATHES:

- POREBA gap bed CNC engine lathe FAGOR 8055 (RETROFIT 2011) CNC control, 56” swing over bed, 70″ swing in the gap, 209” between centers, 5.50” spindle bore, 39” 4-jaw chuck, in/mm threading, steady rest, coolant, chuck & cutting guard with safety interlocks, s/n: 1139-536

- STANDARD MODERN CNC engine lathe with FAGOR 8055 CNC control, 22” swing over bed, 60” between centers, 3” spindle bore, 12” 3-jaw chuck, in/mm threading, steady rest, coolant, chuck & cutting guard with safety interlocks, induction hardened bed ways, s/n: 11917

CONVENTIONAL ENGINE LATHES:

- TOS SU 100 engine lathe with 41” swing over bed, 325” between centers, 4” spindle bore, 40” 4-jaw chuck, speeds to 450 RPM, in/mm threading, steady rest, coolant, ACU-RITE 2 axis DRO, chuck & cutting guard with safety interlock, s/n: 04 29420

- POREBA TR-135 B1/3M gap bed engine lathe with 53” swing over bed, 62” swing in the gap, 137” between centers, 5.5” spindle bore, 40” 4-jaw chuck, speeds to 500 RPM, in/mm threading, steady rest, coolant, ACU-RITE 2 axis DRO, chuck & cutting guard with safety interlock, s/n: 1191-133

- TOS (2006) SN71C gap bed engine lathe with 28” swing over bed, 38” swing in the gap, 160” between centers, 2.90” spindle bore, 20” 4-jaw chuck, speeds to 1000 RPM, in/mm threading, steady rest, coolant, ACU-RITE 2 axis DRO, chuck & cutting guard with safety interlock, s/n: 07007 71 40 06 0112

- TOS (1999) SN71C gap bed engine lathe with 28” swing over bed, 38” swing in the gap, 120” between centers, 2.90” spindle bore, 20” 4-jaw chuck, speeds to 1000 RPM, in/mm threading, taper attachment, steady rest, coolant, HEIDENHAIN 2 axis DRO, chuck & cutting guard with safety interlock, s/n: 07007 71 30 99 0066

- TOS (2005) SN50C gap bed engine lathe with 20” swing over bed , 27.50” swing in the gap, 78” between centers, 2” spindle bore, 12” 4 jaw chuck, speeds to 2000 RPM, in/mm threading, steady rest, coolant, ACU-RITE 2 axis DRO, chuck & cutting guard with safety interlock, s/n 0800 50 20 05 0378

- TOS (2001) SN50C gap bed engine lathe with 20” swing over bed , 27.50” swing in the gap, 78” between centers, 2” spindle bore, 12” 4 jaw chuck, speeds to 2000 RPM, in/mm threading, steady rest, coolant, ACU-RITE 2 axis DRO, chuck & cutting guard with safety interlock, s/n 0800 50 20 01 0045

- TOS (1999) SN50C gap bed engine lathe with 20” swing over bed , 27.50” swing in the gap, 78” between centers, 2” spindle bore, 12” 4 jaw chuck, speeds to 2000 RPM, in/mm threading, steady rest, coolant, ACU-RITE 2 axis DRO, chuck & cutting guard with safety interlock, taper attachment, s/n 0800 50 20 99 0337

- CAZENEUVE HB575 engine lathe with 22” swing over bed, 78” between centers, 2” spindle bore, 10” 3-jaw chuck, speeds to 1500RPM, in/mm threading, steady rest, coolant, ACU-RITE 2 axis DRO, chuck & cutting guard with safety interlock, s/n 8043

CONVENTIONAL MACHINE TOOLS:

- MAS VR8 radial arm drill with 8’6″ arm, 20″ column, speeds to 1750 RPM, 48″x48″x30″ box table, OHIO 8′ diameter powered rotary table, s/n 7278

- MAS VR4 radial arm drill with 4’6″ arm, 12″ column, speeds to 2000 RPM, 28″x28″x18″ box table, s/n 7278

- CHURCHILL PBW universal cylindrical grinder with 13″ swing, 60″ centers, sliding table, 12″ wheel, coolant, filtration, safety guards, s/n 29021

- LANDIS 26X120 O.D. cylindrical grinder with 26″ swing, 120″ centers, 30″ wheel, coolant, filtration, spare wheels and changeover parts

- JONES MODEL 12 vertical shaper with 26″ table, 12″ stroke, coolant, guards

- HANSFORD DAVIS MODEL 5 floor type keyseater, s/n 5-1376

- HYD-MECH (2005) S20 13″x18″ capacity horizontal band saw, miter capability, coolant, s/n 61205216

- DOALL DGP-24 heavy duty floor type gear head drill with 16″x20″ table, speeds to 3360 RPM, s/n 26-8701

- SELLERS 4G floor type tool and cutter grinder with 1 HP, s/n 02-1636

- (2) DELTA 6″ double end pedestal grinders

DIGITAL DYNAMIC BALANCER:

- IRD MECHANALYSIS SERIES III shaft & rotor dynamic digital balancing system with IRD MODEL 290 SERIES III digital control and data acquisition computer, 10′ max swing, 30′ max centers, 30,000 LBS capacity, full safety cage enclosure with interlocks

THERMAL SPRAY WELDING SYSTEMS:

- DEVILBISS 12’X24′ paint booth with rotary table, METCO TYPE 6C thermal combustion wire spray metalizing system, automated overhead gantry type spray gun manipulator with digital 3-axis controls, lights and full safety enclosure

- TAFA-THERMAC robotic metalizing spray weld cell with combustion wire/combustion powder/plasma metalizing spray capability consisting of: TAFA 5120 thermal spray control console, ABB (2005) IRB2400 6-axis gun wielding robot with teach pendant controls, PONTS ROULANTS 2 TON capacity double girder underslung traveling gantry, POREBA 60″X288″ lathe conversion turning manipulator, THERMACH (2014) AT-1000 plasma power supply, THERMAC (2014) AT-3000 plasma spray control system with digital touch screen PLC control, TAFA ARC wire spray system, THERMAC AT-1200 rotary wheel type powder feeder with digital controls, PRAXAIR MODEL 1264 rotary wheel type powder feeder with digital controls, sound proof operator booth with ventilation, full safety enclosure

WELDING & FABRICATING:

- PEARSON 10′ X 0.375″ metal shear with front operated power back gauge, s/n 5861/9

- P&H W12 16,800 LBS capacity tilt and rotate welding positioner, s/n WP2063

- (2) IRCO 2-588 3,000 LBS capacity hydraulic tilt and rotate welding positioners

- RANSOME 25H 2,500 LBS capacity tilt and rotate welding positioner, s/n 165593

- (2) MILLER DELTAWELD 450 MIG boom welders with wire feed, cables, gun and chillers

- MILLER XMT450 portable MIG welder with wire feed, cables and gun

FACTORY EQUIPMENT:

- CANABLAST 10’X18′ blast booth with MARCO (2011) M65-413 pressure pot with gun, ABRATECH cyclonic media recovery system with blower, lights and safety enclosure

- CANABLAST DCM-160 blast cabinet with rotary table and media recovery, s/n MD51L4-0056

- PYROTHERM (2016) HTF-448CB-1800 natural gas fired heat treat and bake oven with 500,000 BTU/HR capacity, 1800 deg F max temp, max 5,000 LBS batch capacity, HONEYWELL digital microprocessor temperature controls, chart recorder, s/n 9980-8187-1

- INGERSOLL RAND (2006) IPN100H-CC NIRVANA rotary screw type energy efficient air compressor with 100HP drive motor, max 145 PSI, s/n NV7379U06159

- INGERSOLL RAND (2006) TMS 0540 refrigerated air dryer, s/n TMS 0540-0630/8162

- DOMINICK HUNTER (2015) BA-DME015 DS breathing air purifier, s/n 15DME112088

- ABRATECH pad type dust collector system with media recovery

ALSO:

- Selection of machining tool holders and fixtures and accessories; (4) heavy duty angle plates; selection of woodworking saws, band saws, floor type drill presses, double end pedestal grinders, cabinets, tables, shop benches; walk behind floor sweeper; gas powered snow blower; welding rod conditioning ovens; rotary tables; small welding positioners; selection of steel frames, jigs, fixtures, shafts and arbors, tempering ovens and MANY MORE ITEMS ADDED DAILY!