Worldwide Industrial Auctions & Liquidations

Large Capacity Machining & Turning Facility

8:00AM - 4:00PM

CNC Horizontal Boring & Milling Machine:

2009 5.125” SNK/Nissin BP130-3.5 CNC Horizontal Boring & Milling Machine, travels: X=137.8”, Y=98.4”, Z=63”, W=27.5”, 62.99” x 86.61”, built in .001” rotary table, full 4th axis, 2500 RPM, CAT#50 spindle taper, 35HP ac motor, 143 PSI coolant thru spindle, helical interpolation, rigid tapping, chip conveyor, 60-position tool changer, 22000# table load capacity, spindle orientation, Fanuc 16-I CNC control, S/N: NN00070

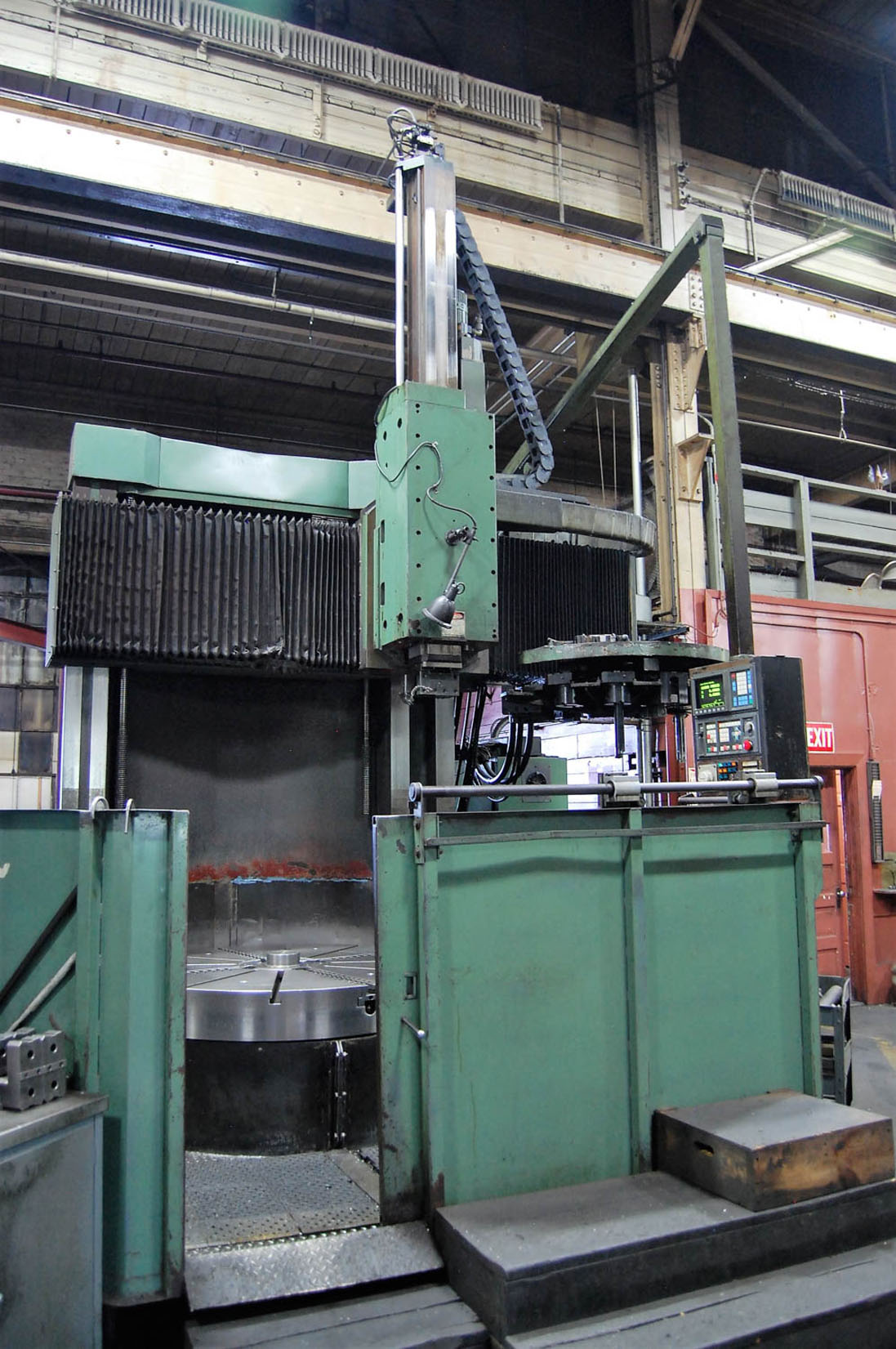

CNC Vertical Boring Mill:

59” Summit M-1500 “Mega Turn” CNC vertical boring mill, 12 station tool changer, Fanuc CNC control, 4-jaw chuck, approximately 63” under rail, 71” swing, 31” travel of ram, 200 RPM, S/N: 138.

CNC Lathes:

46” x 275” CC Tacchi HD/3 600 x 700 series 150L CNC lathe, 33.46” swing oven saddle, 2-720 RPM (stepless vari-speed) (3) drive ranges, DIN55021 size 15” spindle nose, 4.72” spindle bore, 5.5” to 19.6” open roller type steady rest, 3.93” to 19.6” closed roller type steady rest, 11.8” quill stroke on tailstock, metric 80 internal taper on tailstock, toolpost grinding attachment, milling attachment, (2) 4-jaw chucks, bull nose center, Siemens 810T CNC control, S/N: 6640

Okuma LC30-ISC CNC slant bed lathe, tailstock, 12-position turret, approximately 3,000 RPM, chip conveyor, 12” 2-jaw chuck, 15” 4-jaw chuck, OSP-5000L-G control, S/N: 1213

18” x 40” Trak/TRL 1840CSS CNC lathe, camloc spindle, 50-2500 RPM, approximately 2 ¼” hole thru spindle, coolant, proto-trak LX3 control, S/N: 99-823

Vertical Boring Mills:

100” Niles Bement Vertical Boring Mill, (2) swivel ram heads, approximately 72” under rail, approximately 120” swing, face plate, 2-axis DRO, pendant, S/N: 17847

54” Bullard “Spiral Drive” Vertical Turret Lathe, Boring Mill, 4-jaw chuck, 27” ram travel, swivel 5-position ram head, approximately 40” under rail, side head, S/N: 20735

36” Bullard “Cutmaster” Mdl. 75 Vertical Boring Mill, approximately 58” under rail, 26” ram head travel, 5-position turret, side head, 4-jaw chuck, pendant, S/N: 03384

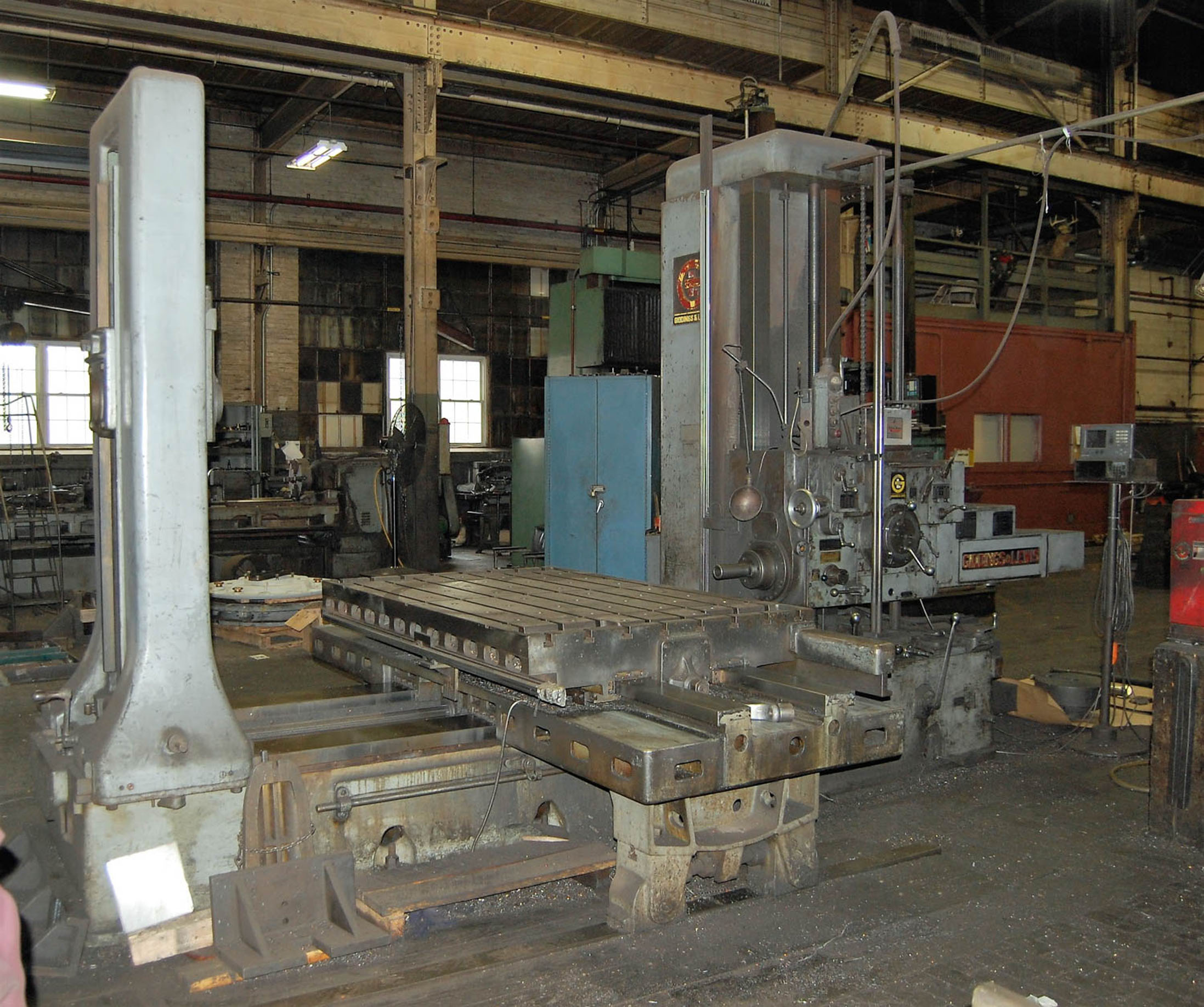

Horizontal Boring Mills:

3” Giddings & Lewis 65-D3-T, #5MT10-1300RPM, 48” x 74” table, approximately 48” vertical head travel, 60” table cross travel, Outboard support Sony Magnescale LH10 & Anilam 550 digital readouts, tailstock, S/N: 150-528-63

5” Giddings & Lewis Fraser 350-T, 60” x 122” table, approximately 72” vertical head travel, 108” table cross travel, 7.5-975 RPM, acu-rite digital readout, 29” right angle head, 40” right angle head, 25” facing head, manual rotary table, (note: right angle & facing heads may be sold separately) S/N: 150-606-60

Angle Plates:

78 1/2” high x 94” wide x 26” deep

48” high x 48” wide x 25” deep, T-slotted

48” high x 24” wide x 30” F-B, T-slotted

Lathes, Including Turret-Type:

24.5” x 264” Monarch 22” CM lathe, 9-400RPM, partial taper attachment, (2) steady rests, modified compound, S/N: 23817

24.5” x 126” Monarch 16” catalog lathe, 24-1000 RPM, tracer, steady rests, 18” 4-jaw chuck, S/N: 40619

13” x 40” South Bend “13” lathe, draw bar, faceplate, S/N:2337TK1

13” x 40” South Bend Mdl. A C4345C Lathe, taper attachment, 3 & 4 jaw chucks, faceplate, steady rest, S/N: 5151KX-12

#5 – 4 ½ Jones & Lamson Turret Lathe, 5-position turret, 4 ½” spindle bore, 20-1000 RPM, bar feed

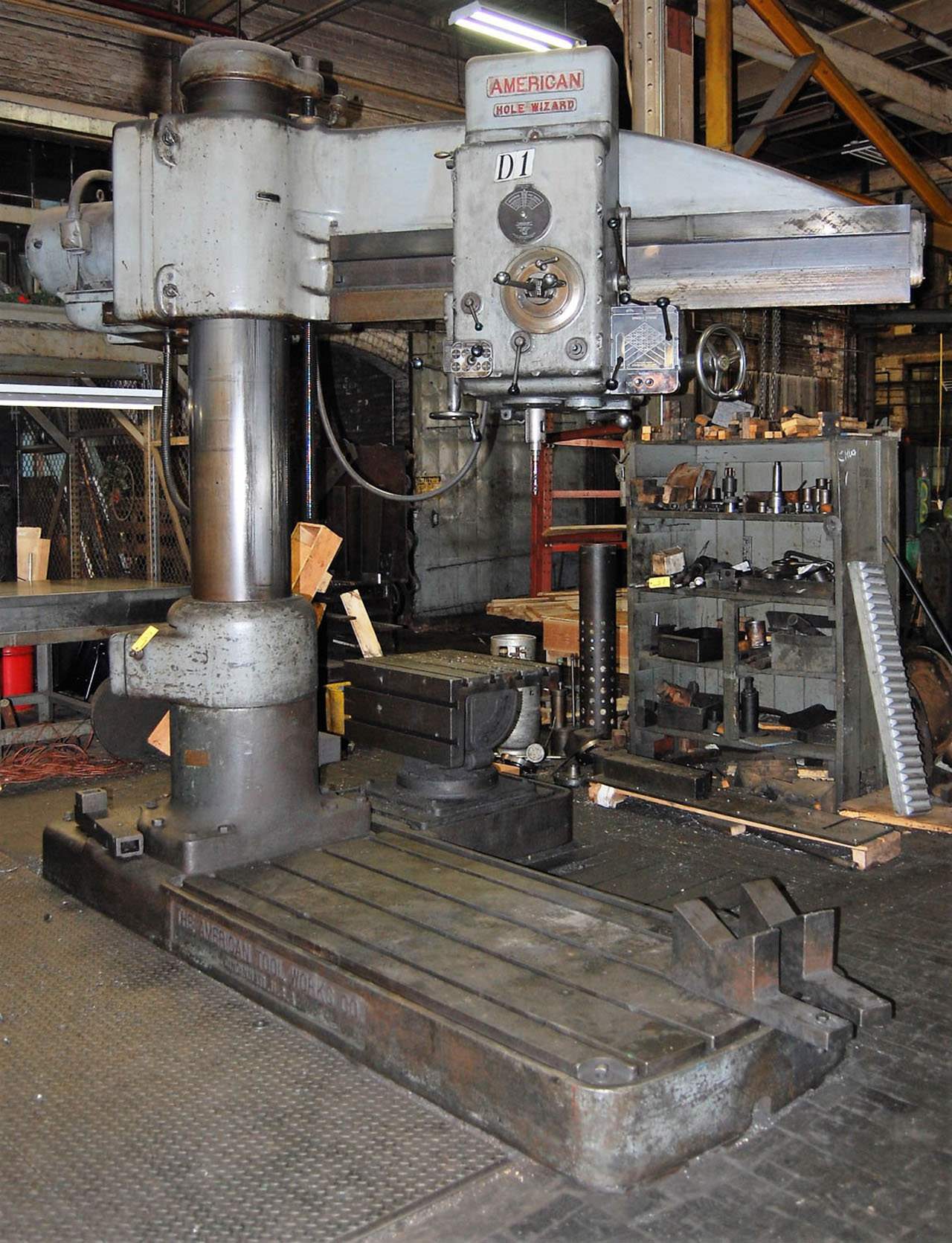

Radial Drill:

6’ x 15” American “Hole Wizard” Radial Arm Drill, #5MT, right angle base, power elevation, 20-1600 RPM, S/N: 6477-42

Wheel Press:

300 Ton (approximately) Horizontal Wheel Press, 15’ long, 72” between rails, hydraulic unit, track mounted support

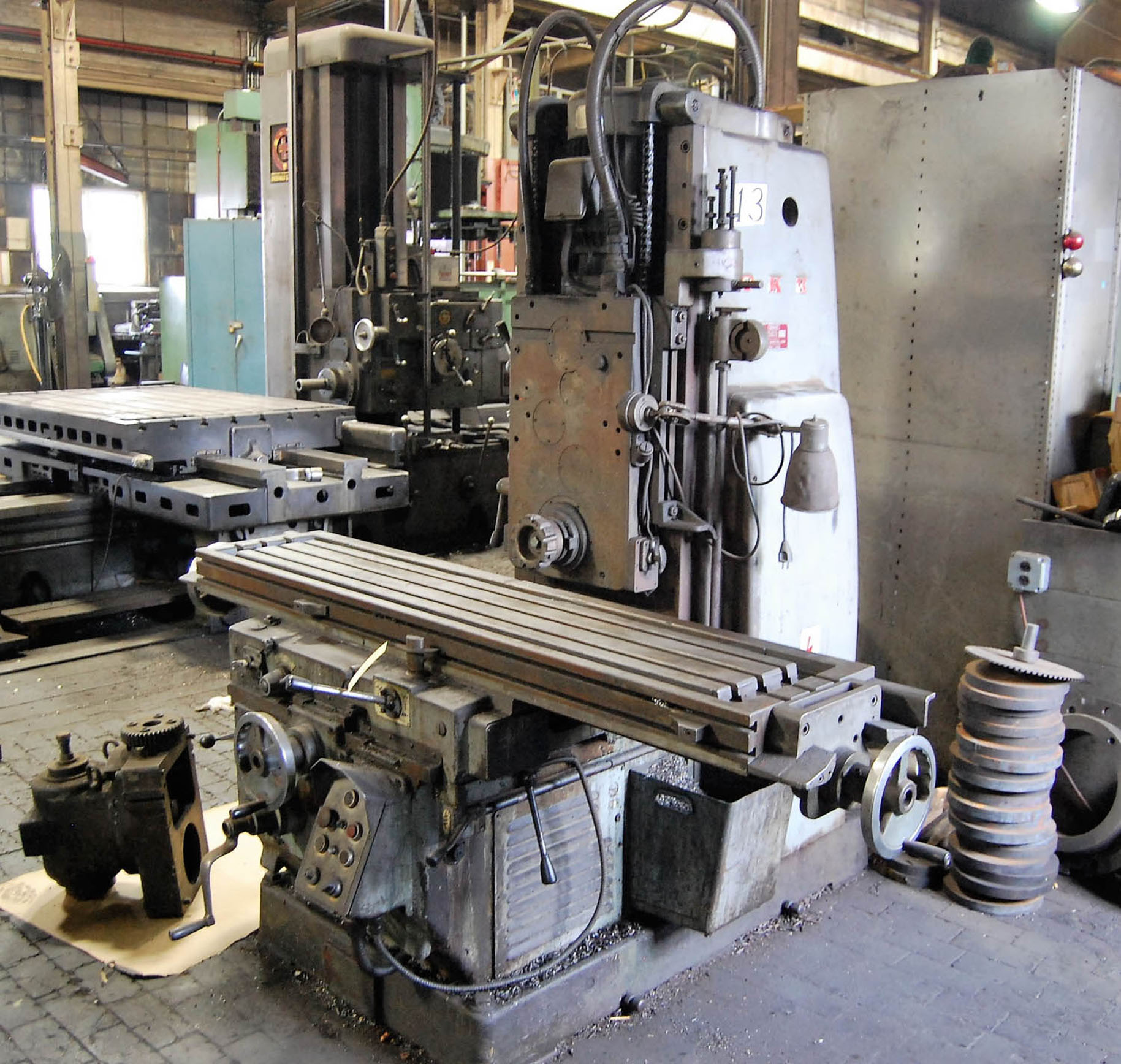

Milling Machines:

OKK MH-3P Horizontal Mill with vertical head, 14” x 65” table, #50 taper, 48-1600 RPM, S/N: 1800-398.

Bridgeport “Series I” vari-speed vertical mill, 9” x 42” table (Power Feed Inoperative), digital readout, 2HP vari-speed, S/N: 216676

Grinders, All Types:

6” x 18” Norton 618SUR Horizontal Surface Grinder, hydraulic feed, wheel presser, S/N: 518SUR-53-H6461

#2 Cincinnati tool & cutter grinder, tooling, S/N: 1D2T5D-102

Black Diamond 2B drill grinder, collets

14” Carboloy double end grinder, tilting tables

Adrian of Oliver drill grinder, 9” diameter wheel, S/N; F49948V

12” Hammond F100 2HP double end pedestal grinder

SAW:

26” Do All MDL. 26-2 vertical bandsaw, 50-2045 FPM, vari-speed, welder, grinder, tilting table, S/N: 54-54161

Miscellaneous: Shop support including inspection items, tooling, CAT#50 tooling, angle plates up to 98”, vises, clamps, etc.