Worldwide Industrial Auctions & Liquidations

Online Auction

Assets of Former LeBlond Factory Service Provider (Willenborg Associates, Inc.)

Complete Facility Closure – Including LeBlond Customer List, Spare Parts, Complete LeBlond Manuals and Drawings, Gray Way Grinder/Planer Mill, Tooling, Accessories, Rolling Stock and Much More!

August 6, 2020

1:00PM ET

Imlay City, MI

Contact for Sale

Inspection Date

TBD

Sale Information

LEBLOND LATHE SERVICE ASSETS:

- CUSTOMER LIST LeBlond Lathe Owners (20,000+ customer list)

- LeBlond Factory OEM Manuals

- Large Quantity of Assembly and Part Prints

- Electrical Prints for LeBlond Models

- Engineering and parts drawings for the Large Servo Shift modification to handle shifting kits

- List of Sub-Contractors Experienced in LeBlond Lathes

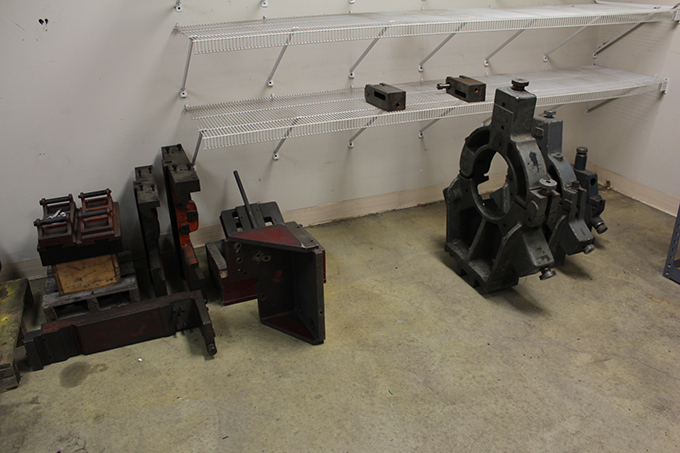

- NEW and USED LeBlond Parts (Manual and CNC) & LeBlond Service & Rebuild Equipment [VIEW COMPLETE LIST]

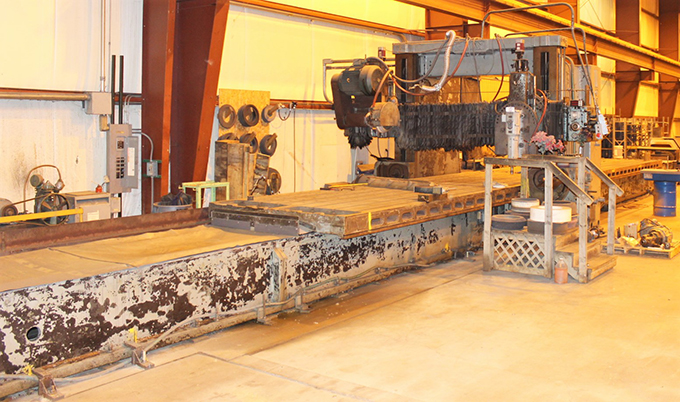

GRAY WAY GRINDER/PLANER MILL

- Travels: Table=576″, Between Columns=85″, Under Wheel=62″, Variable Speed Drives, 50HP Main Wheel Head, 3 HP Angle Wheel Head, Coolant, Mist Collector System

- All new electrics with PLC Control

- Table Ways Machined/Rescraped 2020 for .0001 /ft accuracy

- Stepper motors and drives for Incremental Handwheel Downfeed (added 2010)

- 1 HP Bridgeport Head & Mount for Planer Milling

- (2) OS Walker 24″ x 48″ Magnetic Chucks with Controller

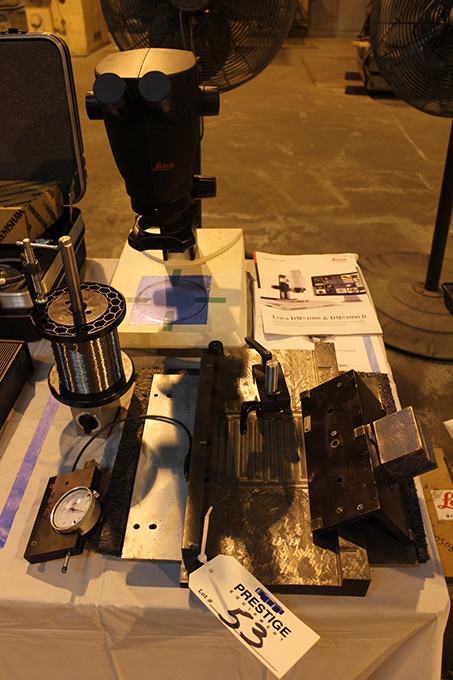

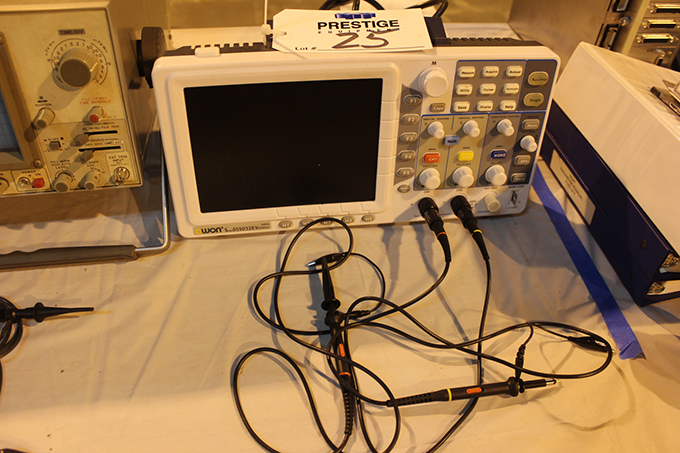

INSPECTION AND MEASUREMENT EQUIPMENT

- Renishaw ML10 Laser Interferometer Measurement System

- Renishaw RX10 Rotary Axis Measurement System

- Renishaw ML10 Gold Standard Laser Interferometer System

- Nikon 6D Autocollimator and Rotary Calibration Master

- Renishaw QC10 Ballbar System

- Leica DMS1000B Microscope Machine Allignment System with Base/Wire System

ADDITIONAL EQUIPMENT

- LeBlond Regal 19” x 102” Lathe REBUILT 2017

- 10” x 20” Monarch EE Lathe

- Bridgeport Vertical Milling Machine

- Baker York FMY200 20,000 Lbs. Capacity Forklift

- Clark 6,000 Lbs. Capacity Forklift

Large Quantities of Parts, Accessories, Motors, Bearings, Scales, Fixtures, Chucks, Dial Gauges, Bore Gauges, Wire, Bearings, Components, Grinding, Miscellaneous