Worldwide Industrial Auctions & Liquidations

Major Fabricating & Heavy Capacity Machining Event

9:00AM - 5:00PM

CNC FLOOR TYPE HORIZONTAL BORING MILL

UNION (PURCHASED NEW IN 2008 FOR OVER $2.2M) P150/I CNC 7-axis floor type horizontal boring mill with HEIDENHAIN iTNC530 CNC control; 5.9″ spindle diameter; column travel X-433.1″, vertical head travel Y-137.79″, column in feed travel Z-31.49″, spindle travel W-29.53″, combined axial travel 59.04″; #50 spindle taper; spindle speeds to 3000 RPM, 84 HP spindle motor; 2868 NM max torque; 0.03937 – 236.22 IPM feed range; 590 IPM rapid traverse; vertical and axial power adjustable operator platform; UNION (2008) DV 20 CNC in feed rotary table with 78.74″ x 98.43″ table size, 44,000 LBS max table capacity, .001º rotary positioning, 59.055″ in feed table travel; D’ANDREA CNC facing head with accessories; RENISHAW 3-D touch probe with radio transmitter; spindle chiller; BURENER (2007) V4 coolant package with flood & thru spindle coolant, high and low pressure pumps and paper filtration; MAYFRAN chip conveyor; (6) 138″ x 69″ x 14″ T-slot floor plates, (floor plates may be offered separately); s/n 1350030

CNC TABLE TYPE HORIZONTAL BORING MILL

UNION (2007) T-130 CNC table type horizontal boring mill with HEIDENHAIN TNC530 CNC control; 5.12″ spindle diameter; 78.74″ x 62.99″ table size; table travel X-98.42″, vertical head travel Y-98.42″, table longitudinal travel Z-59.05″, spindle travel W-29.52″, #50 spindle taper; spindle speeds to 3000 RPM, 84 HP spindle motor; .2 – 590 IPM feed range; 590 IPM rapid traverse; 22,000 LBS max table capacity, 21,100 FT/LBS max clamping force; .001º rotary positioning; 5th axis ready (wired for D’ANDREA CNC facing head); RENISHAW 3-D touch probe with radio transmitter; BURENER (2007) V4 coolant package with flood & thru spindle coolant, programmable nozzle, high and low pressure pumps and paper filtration; OEM UNION PVC-PLEXY enclosure with windows and interlocks; s/n 1360029

CNC VERTICAL BORING MILL

SUMMIT (NEW IN 1997 & RETROFIT IN 2010) CNC vertical boring mill with FAGOR (RETROFIT 2 axis on LH ram in 2010) CNC control; 118.11″ table; 129″ swing; 110″ maximum height under the rail; 98″ rail vertical travel; 57″ LH ram head travel; 30″ RH turret head travel; 100″ side head vertical travel; 39″ side head horizontal travel; table speeds to 92 RPM; 84 HP table drive motor; ±35º LH&RH swivel; 5 position RH turret head; RH side head; SONY DRO’s; coolant; pendant control; s/n 410

CONVENTIONAL MACHINE TOOLS

SUMMIT (PURCHASED NEW IN 1997 FOR $250K) 50-6X320 DC gap bed engine lathe with 50″ swing over bed; 67″ swing in the gap; 320″ distance between centers; 48″ 4-jaw chuck; 6″ spindle bore; speeds to 800 RPM; variable speed; 40 HP; push button pendant control with 4-way rapid traverse; in/mm threading; roller type steady rest; coolant; SONY DRO; s/n 957/7

KING 437 vertical boring mill with 52″ table; 59″ swing; 46″ maximum height under the rail; 34″ rail vertical travel; 45″ vertical ram travel; 37″ horizontal ram travel; 34″ side head vertical travel; 25″ side head horizontal travel; table speeds to 151 RPM in 16 ranges; 30 HP table drive motor; ±60º ram swivel; DRO-PRO 2 axis DRO; coolant; cross rail power elevation; power rapid traverse all directions; s/n 3256

SUPERMAX YCM-2GS universal milling machine with 51″ x 11″ table; vertical spindle speeds to 3800 RPM; horizontal spindle speeds to 1300 RPM; power feed all directions; push button pendant control; ACURITE III DRO; coolant; s/n 9112883

HITACHI SEIKI 5A II TYPE HBT turret lathe with 24″ swing; 12″ 3-jaw chuck; 3″ spindle bore; speeds to 1500 RPM; 6 station turret; s/n E.50496

OLIVER 600 tool and cutter grinder with 3″ capacity; 1.5 HP; coolant; s/n 66304

LEBLOND REGAL engine lathe with 20″ swing; 90″ centers; 15″ 4-jaw chuck; 1.5″ spindle bore; speeds to 425 RPM; s/n E6077

HERMANN KOLB 7′ radial arm drill with 24″ column; speeds to 1750 RPM; (2) 30″ x 36″ x 30″ T-slot box tables; coolant; s/n n/a

OSTER 5K254E47 pipe and bolt threader with 2″ cap; 2 HP; s/n WJ3280

TRENNJAEGER UN/11/60 17″ heavy duty cold cut saw; s/n 3190

PEERLESS 7″ mechanical hack saw; s/n n/a

DOALL TF-1421 tilting head vertical band saw; s/n 337-83494

DOALL 36-W vertical band saw with 36″ throat; 20″ max cutting height; 36″ x 30″ sliding table; blade welder and grinder; s/n 31-52903

CRAFTSMAN 10″ radial arm saw; s/n n/a

ELECTRO ARC 2S portable EDM tap disintegrator with 15 KVA capacity; s/n 14644

DILLON PRO digital crane scale with 50,000 LBS capacity; DILLON digital RFID hand held communicator, s/n n/a

MACHINE TOOL ACCESSORIES

SWIFT OHIO 36″ x 36″ rotary table; s/n 6165

MFG UNKNOWN 30″ x 30″ rotary table; s/n n/a

(2) 139″ x 46″ x 71″ drilled and tapped steel angle plates

(2) 96″ x 24″ x 47″ drilled and tapped steel angle plates

(2) 70″ x 12″ x 38″ drilled and tapped steel angle plates

(4) 55″ x 12″ x 32″ drilled and tapped steel angle plates

(2) 50″ x 20″ x 22″ T-slot steel angle plates

ASTRAL 10’x5’x14″ granite surface plate with stand and rollers; s/n n/a

FABRICATING AND WELDING EQUIPMENT

ROUNDO PS 460/10 hydraulic double pinch plate bending rolls with 18” top roll, 10′ x 1.25″ pre-bend capacity; 10’ x 1-1/2” capacity, 60 HP motor-pump hydraulic unit, hydraulic roll adjustment, roll position indicators, pendant control; s/n OC-2396

BERTSCH MODEL 1008 initial type hydraulic pinch bending rolls with 10” diameter top roll, 8′ x 1/2″ to 16” min. diameter maximum, 5/16” x 8’ at 5 times top roll stainless capacity; 15 10 HP motor-pump hydraulic unit; hydraulic drop end, hydraulic roll adjustment, pendant control; heavy duty moveable base on casters, s/n M-10689 sold new 1984

SMT PULLMAX URSVIKEN KPD 450 hydraulic brake press with 12′ x 450 TON capacity; 124″ between housings; 11.75″ stroke; 10″ max gap; 7.5″ work height; s/n 2747

Assortment of press brake dies, four-way die, adjustable lower die holder

MUBEA KL900 single station hydraulic fabricator with 100 TON capacity; 1 3/16″ to 1″ punching capacity; s/n 050648174566

MG CUTTING SYSTEMS CNC plasma and oxy-acetylene cutting table with RETROFIT BURNY 10 LCD PLUS CNC control; single plasma head; (2) oxy-acetylene heads; 304″ x 201″ water table; travels 336″ x 260″; rack & pinion drive; HYPERTHERM H-601 DC constant power supply; HYPERTHERM H-401 DC constant power supply; KALIBURN INVA precision torch height control; s/n PC4520L-82-968

ARONSON GE500 EDC geared tilt & rotate welding positioner with 50,000 LBS capacity; 84″ x 84″ table; geared power elevation, variable speed table rotation, pendant control; s/n 6612

ARONSON HD500 CS geared tilt & rotate welding positioner with 50,000 LBS capacity; 72″ x 72″ table; SCR drive variable speed table rotation, adjustable base, pendant control; s/n 7110

ARONSON GE500 CS geared tilt & rotate welding positioner with 50,000 LBS capacity; 72″ x 72″ table; geared power elevation, SCR drive variable speed table rotation pendant control; s/n 6918

ARONSON HD100 geared tilt & rotate welding positioner with 14,000 LBS capacity; 48″ x 48″ table; variable speed rotation; pendant control; s/n 66101

ARONSON HD60 geared tilt & rotate welding positioner with 8,000 LBS capacity; 48″ x 48″ table; variable speed rotation, pendant control; s/n 64140

RANSOME #12 geared tilt & rotate welding positioner with 2,500 LBS capacity; 32″ x 32″ table; pendant control; s/n 4165

RANSOME 400P geared tilt & rotate welding positioner with 40,000 LBS capacity; 84″ diameter table; SCR drive variable speed table rotation; pendant control; s/n 2420374

PANDJIRIS / WELDMORE 30-6 geared tilt & rotate welding positioner with 4,000 LBS capacity; 37″ diameter table; variable speed table rotation, pendant control; s/n 800-2490-3

RANSOME 60P geared tilt & rotate welding positioner with 6,000 LBS capacity; 60″ diameter table; variable speed table rotation, pendant control; s/n 2016866

RANSOME 10P geared tilt & rotate welding positioner with, 1,000 LBS capacity; 30″ diameter table; variable speed table rotation, adjustable base; pendant control; s/n 14148

PANDJIRIS 1400-MANIP welding manipulator with, 14’ vertical travel, 14’ horizontal travel, king-pin rotation base, car mounted, LINCOLN IDEALARC SUB ARC welding system; s/n 800-7246-2

MFG UNKNOWN 10 TON capacity tank turning rolls, driver and idler set; s/n n/a

ALL FAB CORP RD-5-1NW 5 TON capacity tank turning rolls, driver and idler set; s/n D-500221J

(2) UNIQUE 5 TON capacity tank turning rolls, driver and idler set; s/n n/a

MILLER DIMENSION 1000 digital ARC welder with cables and gun; s/n LF400235C

MILLER SYNCHROWAVE 300 DX digital TIG welder with cables and gun; s/n n/a

MILLER SYNCHROWAVE 250 DX digital TIG welder with cables and gun; s/n LG480077L

MILLER MP-45E MIG welder with cables and gun; s/n JB534609

MILLER AXCESS 450 MIG welder with cables and gun; s/n LG480057V

(6) MILLER DELTAWELD 650 MIG welder with cables and gun; s/n JB489725; n/a

(2) LINCOLN IDEALARC 1000 ARC welders with cables and gun; s/n n/a

LINCOLN IDEALARC 300-4-300 AC/DC TIG welder with cables and gun; s/n n/a

(10) LINCOLN IDEALARC DC600 MIG welders with cables and gun; s/n n/a

(2) HYPERTHERM MAX200 portable plasma cutters; s/n n/a

(6) HYPERTHERM MAX100D portable plasma cutters; s/n 71-000390; n/a

METALAX 700 SERIES digital portable sub harmonic vibratory stress relief and weld conditioning unit with force inducer; DRO and case; s/n n/a

(2) PHOENIX #5 dry rod electric electrode stabilizing oven; s/n n/a

FACTORY EQUIPMENT

(2) INGERSOLL RAND SSR-EP60 screw type air compressors with digital microprocessor control; 60 HP; 237 CFM @ 125 PSIG; s/n F17128U96306; F17128U96307

INGERSOLL RAND TM 400 TE4 refrigerated air dryer with digital microprocessor control; s/n 96LTM533

CLEANING AND HEAT TREAT FINISHING

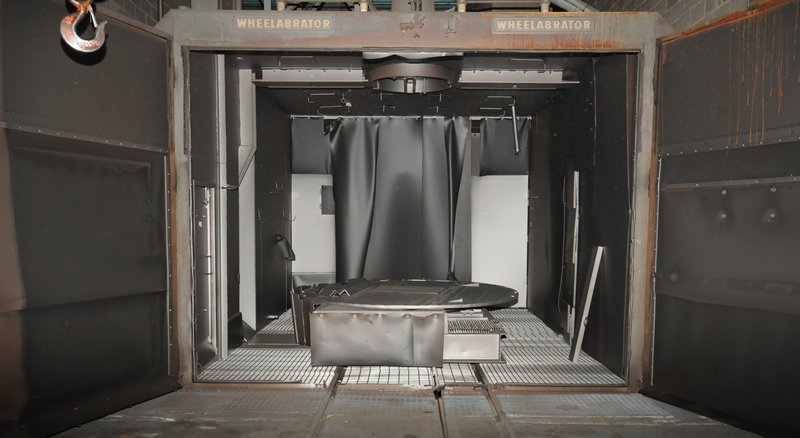

WHEELABRATOR type 12263 rotary table shot blast booth with 110″ table; (2) 20 HP blast wheels; 14′ x 20′ x 11′ enclosure with in-floor down draft twin auger media recovery; dust collector; s/n A109624

NORTH AMERICAN natural gas fired car bottom heat treat oven with 13′ x 10′ x 8′ chamber; (6) NORTH AMERICAN gas burners; HONEYWELL digital temp recorder; s/n n/a

ROLLING STOCK

CATERPILLAR DP70 14,250 LBS capacity outdoor diesel forklift with 148″ max vertical reach; 2 stage high visibility mast; dual outdoor tires; side shift; full cab enclosure with heat; s/n 9CV00327

HYSTER S100XL 10,500 LBS capacity LPG forklift with 111″ max vertical reach; 2 stage high visibility mast; cushion tires; cab enclosure; s/n D004V08298R

GROVE INDUSTRIAL 1012 mobile crane with 35,000 LBS max capacity; 30′ max reach; (3) section boom; DETROIT DIESEL engine; dual pneumatic tires; s/n n/a

GROVE INDUSTRIAL 68 mobile crane with 30,000 LBS max capacity; 30′ max reach; (3) section boom; DETROIT DIESEL engine; dual pneumatic tires; s/n n/a

NEW HOLLAND L783 skid steer loader with diesel engine; run flat tires; s/n 813870

JLG 40FR straight boom lift with 46′ reach; 1000 LBS capacity; air cooled dual fuel GAS/LPG engine; 2 WD; pneumatic tires; s/n 754829

WILD CAT ECONO MV SPL 2154 electric scissor lift with 24′ max reach; 1000 LBS capacity; s/n KB-50551-K2

STRATO-LIFT SRX20 electric scissor lift with 20′ max reach; 1000 LBS capacity; s/n 21002

STRATO-LIFT KRX20 electric scissor lift with 20′ max reach; 750 LBS capacity; s/n 8548

STRATO-LIFT TRX13 electric scissor lift with 13′ max reach; 500 LBS capacity; s/n 8555

STEEL PLATE INVENTORY

10′ x 7′ x 3″ steel plate

23′ x 8′ x 1″ steel plate

16′ x 8′ x 3/4″ steel plate

18′ x 8′ x 2″ steel plate

16′ x 8′ x 1 1/2″ steel plate

10′ x 8′ x 2″ steel plate

18′ x 7′ x 2″ steel plate

25′ x 9′ x 2″ steel plate

21′ x 8′ x 1 3/4″ steel plate

25′ x 8′ x 1 3/4″ steel plate

8′ x 8′ x 3″ steel plate

20′ x 7′ x 2 3/4″ steel plate

20′ x 7′ x 1 1/2″ steel plate

(2) 20′ x 8′ x 2″ (mixed) steel plates

20′ x 8′ x 2″ steel plate

16′ x 8′ x 2″ steel plate

9′ diameter x 3 1/2″ steel plate

(2) 6′ diameter x 2″ steel plates

18′ x 8′ x 1/4″ steel plate

20′ x 8′ x 1 3/4″ steel plate

15′ x 7″ x 1/2″ steel plate

25′ x 8′ x 2″ steel plate

(2) 25′ x 8′ x 3/4″ steel plates

(3) 12′ x 8′ x 1″ steel plates

20′ x 10′ x 2″ (mixed) steel plate

16′ x 8′ x 2″ steel plate

ALSO:

(30+) wall mounted jib cranes with BUDGIT hoists; ASTRAL 10’x5’x14″ granite surface plate with stand; (2) BINKS stainless steel pressure pots with regulators; paint guns and supplies; LARGE QTY of CAT 50 tool holders; tool holder racks and carts; LARGE QTY of perishable tooling consisting of drills; end mills; taps; carbide insert facing and cutting tools; carbide insert boring bars; MILWAUKEE magnetic base drill; SLUGGER magnetic base drill; ROTABROACH magnetic base drill; (5+)BALDOR double end pedestal grinders; LARGE SELECTION OF FAB tooling comprising BESSEY clamps; C-clamps; jigs; clamps; magnetic jigs; NUCLEAR GRADE welding wire and flux; conventional welding wire and electrodes; ENERPACK hydraulic jacks and power packs; LATE MODEL LISTA tool cabinets; (5) self dumping hoppers; hand tools; power tools; precision, inspection equipment and MUCH MORE!