Worldwide Industrial Auctions & Liquidations

Turnkey Opportunity

Precision Manufacturing for Defense & Aerospace Industries

BUSINESS FOR SALE – (2) Facilities in Prime New Jersey Locations – ISO 9001:2015 Certified. Complete Fabrication, Welding, Assembly and Finishing Capabilities - Fully Staffed Operating Business with Approx. $10 Million in Annual Sales

To Be Announced

New Jersey

Sale Information

FEATURED ASSETS:

CNC MACHINING – KEY ASSETS:

- 15+ CNC Machining Centers & Lathes – Haas, Mazak and Okuma Machines as late as 2020!

- 2018 Haas VF-8/40 CNC Vertical Machining Center, 2016 Haas VF-8/40 CNC Vertical Machining Centers, (3) Haas VF-3SS and Haas VF-2SS Vertical Machining Centers

- 2020 Mazak Quick Turn 250MSY CNC Turning Center, 2020 Mazak Variaxis i700 5-Axis CNC Vertical Machining Center, Mazak Variaxis-6305X-II 5-Axis CNC Vertical Machining Center

- 2020 Tsugami BO326-II CNC Swiss Type Lathe with Barfeed

- Okuma MA-5000H CNC Horizontal Machining Center

- Okuma LB3000C-II CNC Lathe

- 2017 Mitsubishi MV-2400R Wire EDM

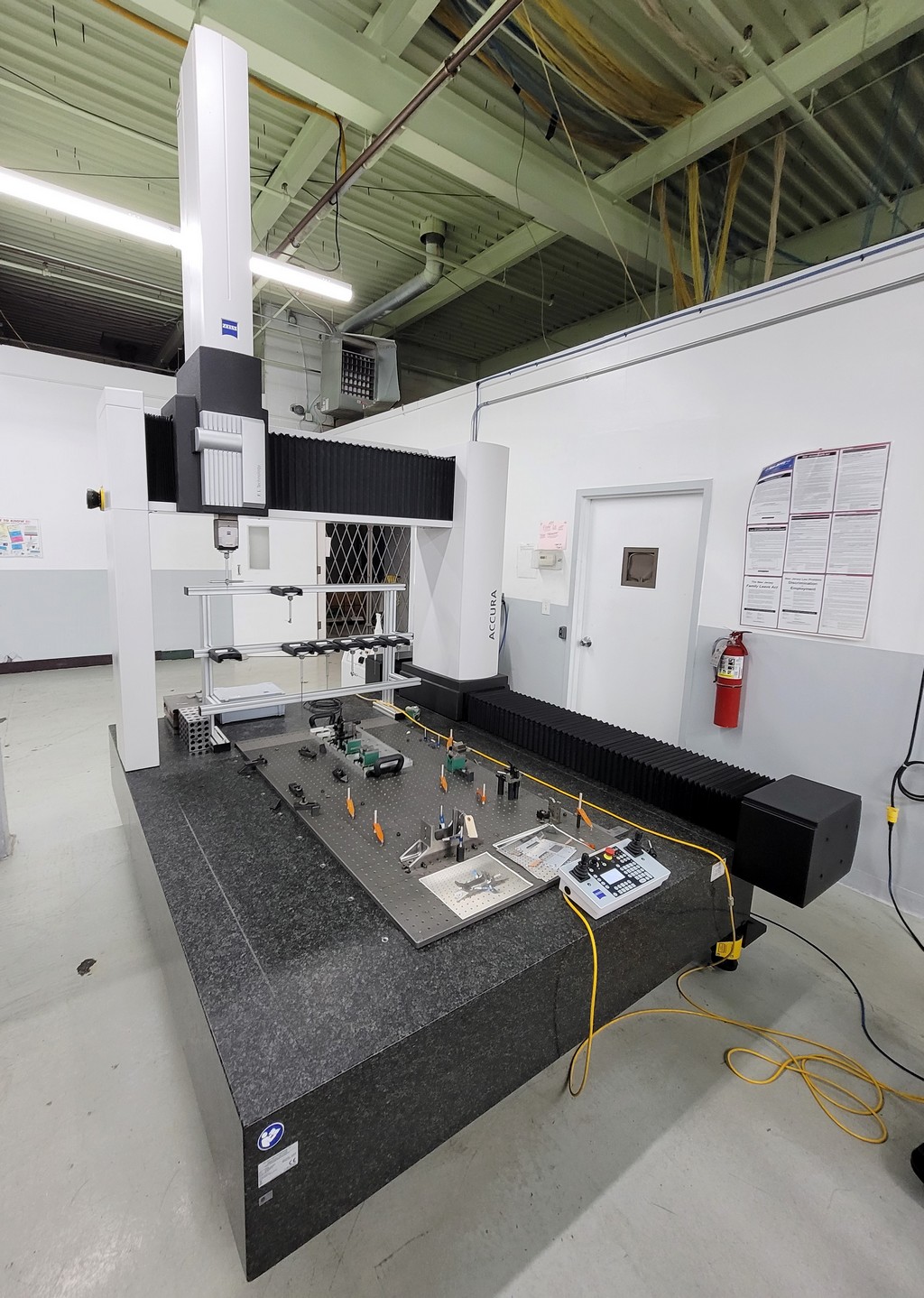

- 2016 Zeiss Accura 12/18/10 Coordinate Measuring Machine

- And Much More!

FABRICATION – KEY ASSETS:

- 2016 Amada FOL-3015AJ CNC Fiber Laser, 4000 kW, Approx. 2500 Cutting Hours

- 2018 Yaskawa Robotic Welding Cell, Dual Robots, Ferris Wheel Positioner, Fronius Power Supplies

- Yaskawa Robotic Welding Cell, Single Robot, Trunnion Positioner, Fronius Power Supply

- Amada FBDIII-1025 CNC Press Brake

- Amada FBDIII-1253 CNC Press Brake

- LVD Strippit Global 20 CNC Turret Punch Press

- Large Quantity of Miller Welders & Dust-Hogs

- Full Plating, Powder Coating and Painting Systems

- And Much More!

COMPANY SPECIALIZING IN:

MANUFACTURING ENGINEERING:

- Digital Design & Simulation of Robotic Welding Processes.

- Complex Multi-Axis Machining Fixtures.

- Digital Design of Assembly Lines for Individual Products.

- Custom Packaging Solutions.

- Small Arms Mounts & Accessories Specialist.

- Power Distribution & Electronic Enclosure Specialist.

- Hydraulic System Assembly & Pressure Testing.

- Assembly Fixtures & Digital Work Instructions

SHEET METAL FABRICATION & FINISHING:

- Punch Press Cell

- Silk Screening & Painting

- Laser Cutting Equipment

- Plating Line & Automated Drying Rack

- Press Brakes & Example Parts

FORMING/BENDING:

- (4) Press Brakes at varying tonnages to tackle components up to 5/8″ thick

- Extensive inventory for Press-Brake Tooling to form a variety of part geometries, bend angles & bend radii

- Developed processes to cold-form 0.060″ – 0.125″ thick Titanium with no cracking

ROBOTIC WELDING:

- (2) Robotic Welding Cells

- First cell features (1) Robot and (2) Positioning Tables

- Second cell purchased in 2019, (2) Robots & (2) Positioning Tables

- Continuous processing can be achieved as parts are loaded/unloaded on (1) table while welding on 2nd table

LASER CUTTING:

- Purchased in 2019, state of the art Amada Fiber Optic 4kW Laser Cutter will cut profiles to within +/ 0.003” for parts with material thicknesses ranging from .062” – .375″

- Machine has (2) shuttle tables to enable continuous processing

- Surrounding the machine is support equipment such as an overhead hoist to aid with material handling, manual deburring stations and a timesaver which automates flat deburring operations

- Specialized parameters for cutting Titanium. These parameters cut Titanium parts while reducing the chance of crack propagation during subsequent forming operations

- Machine can cut Aluminum up to ½” thick and Steel up to 7/8” thick, while retaining edge quality

PRECISION MACHINING:

- 3-Axis Milling Centers – (8) Machines with a Max Envelope of 36″ x 60″

- 4-Axis Horizontal Milling Center with Pallet Changer

- Multi-Axis Turning Centers & Screw Machining – 5X Machines with Sub-Spindles & Live Tooling

- 5-Axis Milling Center – 2X Machines

PLATING, PAINTING & SCREEN PRINTING:

- Liquid Painting for Commercial Applications

- Chemical Agent Resistant Coatings for Military Applications

- Chem-Film and Iridite Lines for Aluminum Components

- Powder Coating for Commercial and Military Applications

- World Class Screen Printing

- Overhead Conveyor System for High Volume Production Runs