Worldwide Industrial Auctions & Liquidations

SOLD! Former Assets of Mitsubishi Hitachi Power Systems Canada, Ltd.

LATE MODEL FPT CNC HORIZONTAL BORING MILLS:

FPT SPIRIT 200 Ram Type CNC Horizontal Boring Mill, 6.3” Spindle Dia., Heidenhain iTNC 530 CNC Controls, X-Axis 551″ (13M), Y-Axis 196″ (5M), Z-Axis (Ram Travel) 59”, W-Axis (Quill Travel) 35.4”, 75 Ton Capacity Infeeding Rotary Table, V-Axis (Table Infeed) 78”, 120-Position ATC, Head Changer Tower, TUPC 2-Axis Universal Head, Probe, Heidenhain iTNC 530 CNC Control, 95 HP Spindle Motor, NEW 2013

FPT RONIN Ram Type CNC Horizontal Boring Mill, Heidenhain iTNC 530 CNC Controls, X-Axis 157″ (4M), Y-Axis 98″ (2.5M), FPT 15 Ton Capacity Infeeding Rotary Table, Table Size 78” x 78”, V-Axis (Table Infeed) 59”, 80-Position ATC, Spindle Speeds to 7,000 RPM, Head Changer Tower, TUPC 2-Axis Universal Head, D’Andrea Facing Head, Spindle Extension Head, Probe, Heidenhain iTNC 530 CNC Control, 65 HP Spindle Motor, NEW 2012

FPT RONIN Ram Type CNC Horizontal Boring Mill, Heidenhain iTNC 530 CNC Controls, X-Axis 236″ (6M), Y-Axis 118″ (3M), FPT 50 Ton Capacity Infeeding Rotary Table, Table Size 98” x 98”, V-Axis (Table Infeed) 78”, 120-Position ATC, Spindle Speeds to 7,000 RPM, Head Changer Tower, TUPC 2-Axis Universal Head, D’Andrea Facing Head, Probe, (2) Spindle Extension Heads, Heidenhain iTNC 530 CNC Control, 65 HP Spindle Motor, NEW 2013

LARGE CAPACITY TOSHIBA CNC FLOOR TYPE HORIZONTAL BORING MILLS:

(2) TOSHIBA BF-130B CNC Horizontal Boring Mills, Tosnuc 888 Controls, X-Axis 295″, Y-Axis 137″, Spindle Speeds to 1600 RPM, Toshiba BF30/35D Infeeding CNC Rotary Table, Floor Plates

(2) TOSHIBA BF-130A CNC Horizontal Boring Mills, Fanuc 15M CNC Controls, X-Axis 295″, Y-Axis 137″

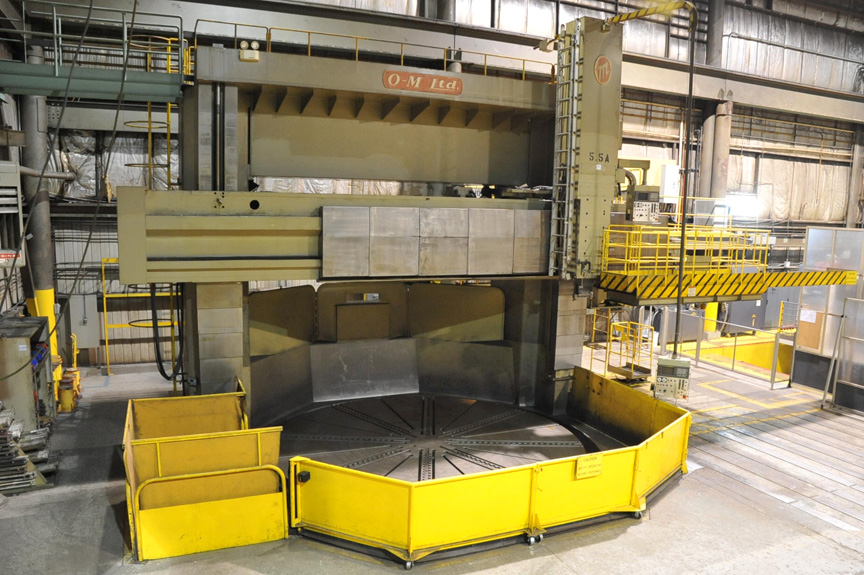

CNC VERTICAL BORING MILLS:

(2) O-M Ltd. TMD-55/60N CNC Double Column Vertical Boring Mills, Fanuc 18-T CNC Controls, 216″ Table Diameter, 236.52″ Turning Capacity, 145″ Work Height, .03-45 RPM, 132,000 Lb. Table Capacity, 100 HP Table Drive

O-M Ltd. TMD-55/60N CNC Double Column Vertical Boring Mills, Fanuc 18-T CNC Controls, 216″ Table Diameter, 236.52″ Turning Capacity, 175″ Work Height, .03-45 RPM, 132,000 Lb. Table Capacity, 100 HP Table Drive

O-M Ltd. VT5-16N CNC Vertical Boring Mill, Fanuc 18-T CNC Controls, 66.7″ Table Diameter, 78″ Turning Capacity, 63″ Work Height , 22,000 Lbs. Table Capacity, 75 HP Table Drive

Toshiba TSS-30/55 CNC Openside Vertical Boring Mill, Fanuc 15T CNC Controls, 118″ Table Diameter, 216″ Turning Capacity, 110″ U/R, 2.5-80 RPM, 44,000 Lbs. Table Capacity, 50 HP Table Drive

LATE MODEL MAZAK CNC LATHES INCLUDING:

Mazak e-670HS II/4000U 5-Axis CNC Turning & Milling Center, 42” Swing, 157″ Between Centers, (2) Spindles: Turning Spindle: 10.2” Bore, 1,000 RPM, 60 HP, Milling Spindle: 10,000 RPM, 49 HP, Mazatrol Matrix 2 CNC Control, 32” Chuck, 5-Axis Contour Milling, Thru Spindle Coolant, 120 Station Automatic Tool Changer, Programmable Hydraulic Steady Rest, Auto Tool Eye, Laser Rotary Tool Length Measurement, Overload Detection System, Mist Collector, Thru Tool Spindle Air Blast, Chip Conveyor, NEW 2013

(2) Mazak Integrex E420-H ST II 5-Axis CNC Turning & Milling Center, 26.38” Swing, 79.80” Machine Length, (2) Spindles, 78.74” Distance Between Spindles, Turning Spindle: 3.58” Bore, 4000 RPM, 40 HP, Milling Spindle: 35-12,000 RPM, 30 HP, Upper and Lower Turrets, 9-Station Lower Turret, Mazatrol Matrix CNC Control, 5-Axis Contour Milling, 40 Station Automatic Tool Changer, Coolant Thru Milling Head, Chip Conveyor, NEW 2011

Mazak i-200ST 5-Axis CNC Turning & Milling Center, 25.91” Maximum Machining Diameter, 59.80” Maximum Machining Length, (2) Spindles, Main Spindle: 8” Chuck, 6,000 RPM, 30 HP, Milling Spindle 12,000 RPM, 240 Deg. B-Axis, 30 HP, 36 Station Automatic Tool Changer, Mazatrol Matrix 2 CNC Control, 5-Axis Contour Milling, C-Axis Contouring (0.0001 Deg.), Chip Conveyor, NEW 2013

ADDITIONAL HEAVY MACHINING AND FABRICATING INCLUDING:

TOSHIBA MPE-2140 CNC BRIDGE MILL, 157″ x 63″ Table, 82″ Between Columns, 60 ATC

FLOW AF-6080 5-AXIS CNC Waterjet, 60,000 PSI, 72” x 96” Work Envelope

DAVI MCB-3053 4 ROLL DOUBLE PINCH PLATE BENDING ROLL, 10’ x 2” Capacity, New 2003

DAVI MCB-3070 4 ROLL DOUBLE PINCH PLATE BENDING ROLL, 10’ x 3-1/2” Capacity, New 2008

ADDITIONAL EQUIPMENT INCLUDING: (6) ESAB WELDING MANIPULATORS, LF WELDING MANIPULATOR, 50+ SETS OF ROMAR AND OTHER TANK TURNING ROLLS, LARGE CAPACITY PAINT AND BLAST FACILITIES, ROLLING STOCK, ESAB AVENGER FLAME CUTTER, LARGE QUANTITY OF WELDING POSITIONERS UP TO 120,000 LBS. CAPACITY, INSPECTION, MAINTENANCE, MATERIAL HANDLING VEHICLES AND MUCH, MUCH MORE!!!!