World's Leading Provider of Used Machinery

Peddinghaus: Transforming Structural Steel Fabrication with Advanced Machinery

Peddinghaus is a renowned name in the world of structural steel fabrication, offering a range of machines that are integral to the steel industry. In this article, we’ll explore the diverse offerings of Peddinghaus and how they contribute to the efficiency and precision in structural steel fabrication.

A Legacy of Innovation and Quality

Peddinghaus, a company with a rich history dating back over a century, has established itself as a leader in the structural steel fabrication machinery sector. Their commitment to innovation and quality has been a constant throughout their evolution, adapting to the changing needs of the industry.

Comprehensive Product Range

Peddinghaus offers an extensive range of machines that cater to various aspects of steel fabrication. This range includes beam drill lines, plate processors, angle lines, and band saws, among others. Each machine is designed with precision and efficiency in mind, ensuring high-quality output for complex structural steel projects.

Beam Drill Lines

Peddinghaus’ beam drill lines stand at the forefront of structural drilling technology. These machines, known for their robust construction and high-speed operation, are capable of handling a wide range of beam sizes and profiles. They integrate advanced software that allows for precise positioning and drilling, ensuring that every hole is accurately placed according to specifications. The automation features reduce manual intervention, leading to significant improvements in production timelines and labor efficiency.

Plate Processors

The versatility of Peddinghaus plate processors makes them a valuable asset in any fabrication shop. Capable of performing multiple operations like drilling, punching, and plasma cutting on a single machine, they eliminate the need for multiple setups and equipment. This multifunctionality not only saves space on the shop floor but also accelerates production cycles. The integration of intelligent nesting software maximizes material utilization, reducing waste and cutting costs.

Angle Lines

Peddinghaus’ angle lines are engineered for the high-speed processing of angle and flat bar stock. These machines combine punching, shearing, and marking capabilities in a compact footprint. With the ability to process a wide range of sizes and thicknesses, they are suitable for various applications from tower construction to bridge building. The automatic loading and unloading systems further enhance productivity by minimizing manual handling.

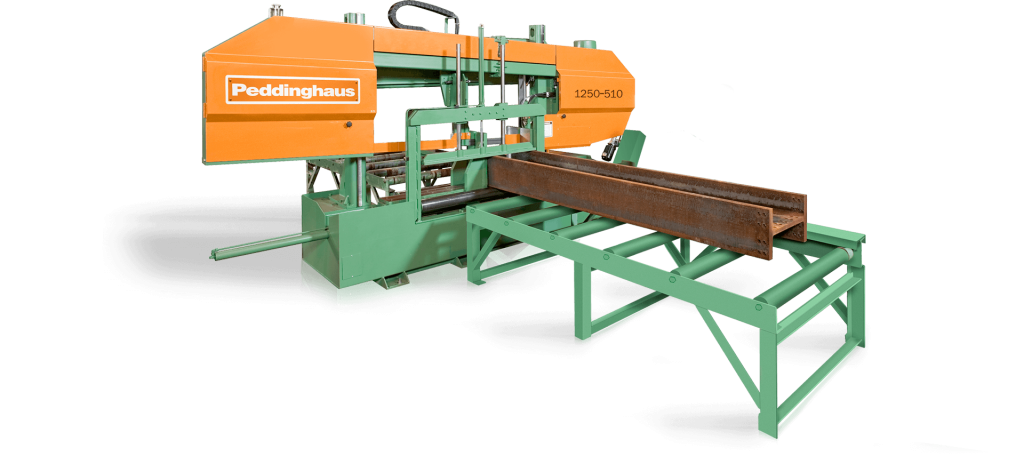

Band Saws

The band saws from Peddinghaus epitomize precision and efficiency in the cutting of structural steel. Designed to accommodate a broad spectrum of structural profiles, these saws deliver clean, accurate cuts with minimal material waste. The saws feature automatic feed mechanisms and programmable cutting cycles, optimizing cutting speeds and blade life. This leads to faster turnaround times and reduced operational costs.

Embracing Technology for Enhanced Performance

Peddinghaus machines are at the cutting edge of technology, integrating CNC controls, automated material handling systems, and proprietary software solutions. This embrace of technology not only enhances the precision and efficiency of their machines but also provides users with unparalleled control over their fabrication processes. The software solutions offered by Peddinghaus enable seamless workflow management, from design to finished product, ensuring that projects are completed accurately and on schedule.

Supporting a Sustainable Future

In line with global efforts to promote sustainability, Peddinghaus machines are designed to be as environmentally friendly as possible. By optimizing energy consumption and reducing waste materials, these machines contribute to more sustainable fabrication practices. Peddinghaus’ commitment to sustainability extends to their manufacturing processes, where they strive to minimize environmental impact.

Global Reach and Support

Peddinghaus’ commitment to customer service is evident in its extensive global network of support and service centers. This network ensures that wherever a Peddinghaus machine is in operation, expert assistance, maintenance, and spare parts are readily available. This comprehensive support system is crucial for minimizing downtime and maintaining high levels of productivity, making Peddinghaus a trusted partner in the structural steel industry.

Conclusion

Peddinghaus machines embody the company’s commitment to quality, innovation, and customer satisfaction. With their advanced technology and comprehensive support network, Peddinghaus is not just a supplier but a partner in the structural steel fabrication industry. As the demand for more complex and high-quality structural components grows, Peddinghaus’ machinery and support services will continue to play a pivotal role in meeting these challenges, further cementing their position as leaders in the field.

Prestige Equipment is proud to offer numerous Peddinghaus machines, such as these popular models:

- PCD 1100 Advantage Beam Drills

- HSFDB 2500 Plate Processors

- Anglemaster 623, 823 & HD Angle Lines

- DG-1250, DG1100 Mitering Band Saws

- 1250-510 Straight Cut Band Saws

Click the following link to view our available Peddinghaus machines: VIEW PEDDINGHAUS INVENTORY

Contact us today for more information on our available Peddinghaus machines.