World's Leading Provider of Used Machinery

Top CNC Machine Tool Brands – Haas, DMG Mori, Mazak, Okuma, Doosan

Introduction

In the realm of modern manufacturing, CNC machinery stands as a cornerstone of innovation and efficiency. These sophisticated machines can transform digital designs into tangible products with incredible precision and speed, revolutionizing industries from aerospace to automotive. Selecting the right CNC equipment is pivotal for any business, impacting productivity, accuracy, and overall success. This article discusses some of the leading CNC brands, exploring their products and the unique features that render them as industry leaders.

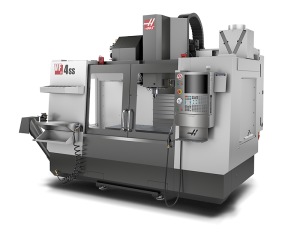

1. Haas Automation

Overview: Founded in 1983 in Oxnard, California, Haas Automation has grown into one of the largest builders of CNC machines in America. Known for its extensive product line and affordable pricing, Haas has established a strong global presence, catering to various industries.

Key Products:

- Haas VF Series: These vertical machining centers are renowned for their versatility. Ranging from small-footprint models perfect for tight spaces to large-capacity machines for heavy workpieces, the VF Series caters to a broad spectrum of machining needs.

- Haas ST Series: These CNC lathes offer high performance in turning applications. Equipped with high torque and rigid construction, the ST Series is adept at handling a wide range of materials with precision.

- Haas UMC Series: These 5-Axis universal machining centers provide a cost-effective solution in order to reduce setups and increase accuracy. CNC users can conduct 3+2 machining applications as well as simultaneous 5-axis machining.

- The Haas product line also includes EC Series horizontal machining centers, Haas rotary tables and indexers, tooling and more.

- Unique Selling Points: Haas is celebrated for its user-friendly interfaces, making its CNC control widely used by both beginners and experts. Additionally, their robust construction ensures durability and long-term reliability, providing excellent value for money.

2. DMG Mori

Overview: DMG Mori, a global name in the CNC industry, is synonymous with innovation and quality. This German-Japanese alliance focuses on advanced technology, precision engineering, and sustainable solutions.

Key Products:

- DMU MonoBlock Series: These are advanced 5-axis milling machines offering exceptional precision. They are ideal for complex geometries and high-quality surface finishes in aerospace, automotive, and die/mold applications.

- NLX Series: This series of universal turning centers is known for its high rigidity, stability, and precision. They are capable of handling a diverse range of machining tasks, from heavy-duty cutting to high-speed finishing.

- Unique Selling Points: DMG Mori’s integrated automation solutions and focus on digitalization set it apart. The brand is at the forefront of Industry 4.0, offering smart manufacturing solutions with enhanced connectivity and data analytics.

3. Mazak

Overview: With a century of experience, Mazak has positioned itself as a leader in CNC technology. This Japanese brand is known for its innovative solutions and commitment to manufacturing excellence.

Key Products:

- INTEGREX Series: These multi-tasking machines combine turning, milling, drilling, and tapping capabilities. They are ideal for producing complex parts in single setups, enhancing productivity and reducing lead times.

- VARIAXIS Series: These 5-axis machining centers are designed for high-speed and high-precision machining. They are particularly effective for components requiring complex contouring and multi-angle machining.

- Unique Selling Points: Mazak’s iSMART Factory concept integrates advanced manufacturing technologies with IoT solutions, optimizing efficiency and productivity. Additionally, their extensive service and support network ensure customer satisfaction and machine uptime.

4. Okuma

Overview: Okuma, founded in 1898 in Japan, is one of the world’s oldest CNC manufacturers. The brand is renowned for its high-quality, reliable, and innovative machinery.

Key Products:

- Okuma M Series: These milling machines are celebrated for their high precision and superior surface finish. They are suitable for a wide range of applications, from die/mold making to aerospace parts manufacturing.

- LB Series: These CNC lathes are known for their power, precision, and versatility. They excel in everything from basic turning operations to complex multi-axis machining.

- Unique Selling Points: Okuma’s Thermo-Friendly Concept ensures exceptional thermal stability and accuracy. The open-architecture OSP-P control system allows for high customization and integration with advanced software.

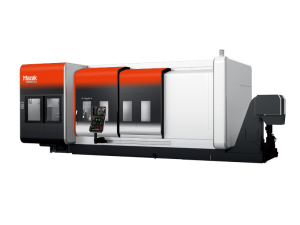

5. Doosan/DN Solutions

Overview: Doosan Machine Tools was established as Chosun Machine Works in 1976 in Changwon, South Korea. Throughout the years, Doosan has focused on technological innovation to stay competitive in the global market. It has continuously developed and introduced new CNC machine tools with advanced features and capabilities.

Key Products:

- CNC Lathes: Doosan’s CNC lathes are designed for precision turning operations. They offer a range of models with different specifications to meet the needs of various applications, from small components to large workpieces. Features may include multi-axis capabilities, high spindle speeds, and advanced control systems for efficient machining.

- Vertical Machining Centers (VMCs): Doosan’s Vertical Machining Centers are used for milling, drilling, and tapping operations on a variety of materials. They come in different sizes and configurations, including 3-axis, 4-axis, and 5-axis machines, with options for high-speed machining, rigid construction, and advanced tool management systems.

- Horizontal Machining Centers (HMCs): Doosan offers Horizontal Machining Centers for high-precision horizontal milling operations. These machines are suitable for machining complex workpieces with multiple sides in a single setup. They feature robust construction, high spindle speeds, and options for pallet changers and automation systems for increased productivity.

- Boring Mills: Doosan’s line of boring mills is designed for heavy-duty machining of large workpieces. These machines are equipped with powerful spindles, high torque, and large work envelopes to handle a wide range of applications, including boring, milling, drilling, and tapping of large components for industries such as aerospace, energy, and heavy machinery.

Conclusion

The landscape of CNC machinery is diverse, with each brand bringing its unique strengths and specialties. Whether it’s Haas’s user-friendly designs, DMG Mori’s digital solutions, Mazak‘s smart factories, Okuma’s thermal stability, or Doosan’s/DN Solutions reliability and wide lineup of machine tools, these brands embody the pinnacle of CNC innovation.

When selecting CNC machine tool equipment, it’s crucial to consider not only the machine’s capabilities but also the technology, support, and values of the brand behind it. By choosing wisely, manufacturers can significantly enhance their operations, ensuring precision, efficiency, and success in an ever-evolving industrial world.